| Brand Shanghai nine | Model Shanghai nine | ||

| range | 500 (kg) |

1, integrating control of bulk material gap

direct weighing in for some difficult logistics, the product can be considered that bulk weighing method. The method is to add a link in the middle of the material static measurement equipment.

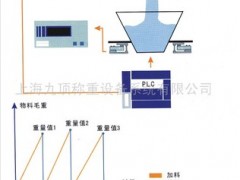

shown: the weighing hopper to receive the above materials, whenever it receives a certain amount, closing the mouth of the discharge, the steady-state at this time the weight of the total weight of the cumulative value of income, and again open its discharge port, discharge all the hopper material. Move to the next cycle. Weighing each weighing bucket B are in the static, so the total integrating very high precision.

features: simple structure, high precision and high reliability.

use the pull or pressure sensor modules weighing module, weighing controller, PLC, and can constitute a simple bulk gap control system integrator.

Totalizer control of bulk material gap in two ways: first is the number of bulk weighing the total amount of volume calculation, the total weight obtained; The second is the overall goal of a given weight, control the amount of the accumulated dispersion volume calculated.

2, integrating control of a continuous bulk

direct weighing in for some difficult logistics, the product can be considered that bulk weighing method. The method is to add a link in the middle of the material static measurement equipment.

as shown: A constant struggle to receive the above materials to provide materials to the bucket B; B Doo Doo as the weighing, whenever it receives a certain amount, that is fighting off the discharge port A, will be at this time steady-state value of the cumulative weight of the total weight of value to enter, then open the discharge port, all in all the materials into the bucket B C bucket to go; C there is always fighting material, and from out under the discharge opening. Throughout the course of their work, progress under the gate and the discharge opening of the logistics has always been. Weighing each weighing bucket B are in the static, so the total integrating very high precision.

features: high accuracy, high reliability, high speed, does not affect the process.

use of pull or pressure sensor modules weighing module, and a simple PLC, to form a continuous bulk material integrating control system.

![[Sold 50] supply control system for ultra-low-cost quantitative](http://www.chinaexporter.com/file/upload/201105/31/11-02-03-56-233732.jpg.thumb.jpg)