filling ratio of the amount of filling (filling ratio) is the plastic filler masterbatch product key indicators, which involves the fundamental economic benefits of plastic products companies, while this is a complex technical problems . Over the years, the general PE , PP plastic filling rate has been hovering around 30-40% below, simply can not get a breakthrough. How to ensure the quality of plastic products and can achieve higher fill volume (filling ratio) has been the various filler business research. My company after years of painstaking research and development, and finally in 2011 was overcome technical bottlenecks, made a fundamental breakthrough, fill volume (filling ratio) greatly improved, some of the PE, PP products meet or exceed 50%, plastic products companies to significantly reduce production costs.

Welcome to the plastics business with us, can you send us finished plastic products, we do test for product analysis, customize one of the most in line with the product filler, not only does not reduce the quality of the product, there will be many performance improvements and improved; fill rates may also be updated to achieve the height of many PE , PP fill filler used than the general market by about 5-10 ' percentage points.

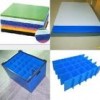

[Application] is widely used in drawing, blow molding, injection molding, sheet, sheets and other products as well as various plastic filling and modification is to reduce the cost of plastic products, the best filler .

Application of plastic products including PO

, PE, PS , PP such as injection molding or blown film, blow products, sheet products, such as: shopping bags, food bags, garbage bags, bottles, rain cloth, table cloth, food box, fast food boxes, pipe, sheet, hollow sheet, electrical enclosure, packing tape, woven bags, woven, striped cloth, cast film, plastic flowers, drink cups, bowls, plates, knives, forks, spoons and other products. [Features]

1

) uniformly dispersed in the products, good compatibility with plastics;

2) size plastic particles with very basic, the perfect grain type, high brightness;

3 ) can maintain products and basic mechanical properties of the original strength;

4) dimensional stability and improved performance and other indicators;

5 ) extremely easy to use, no need to change the production process;

6) higher fill ratio, the cost savings;

7) non-toxic, tasteless, environmental protection.

] [Price advantage its own raw material powder stone mining system, the price advantage.

1 [

] product variety), blown film series filled masterbatch: (for PO, PE , PP, milky white, transparent, transparent); 2

), blow molding hollow filled masterbatch products series: (for PO , PE, PP , white, ultra white); 3

), filled masterbatch sheet series: (for PO, PE , PP, PS , etc., white); 4

), drawing filled masterbatch: (for PO , PE, PP , etc., white); 5

), injection filled masterbatch: (for PO, PE , PP, PS , etc., milky white, transparent, transparent); 6

), the corresponding products according to customer requirements.

), blow molding hollow filled masterbatch products series: (for PO , PE, PP , white, ultra white); 3

), filled masterbatch sheet series: (for PO, PE , PP, PS , etc., white); 4

), drawing filled masterbatch: (for PO , PE, PP , etc., white); 5

), injection filled masterbatch: (for PO, PE , PP, PS , etc., milky white, transparent, transparent); 6

), the corresponding products according to customer requirements.

Model No. Product List :

set | powder body surface area cm2 / g | | reference range of applications grid usage (% | ) price (yuan / kg ) | |

| C600-C800 | PE | 15000-20000 | low blow film, casting, rolling film |

Total: 0 [Show All] Related Reviews

More »Our Others Products copyright 1999-2024 旭东国际 chinaexporter.com 津ICP备05014874号

|