Tempered glass could have spontaneous breakage without receiving any external force, which is the nature of tempered glass. The reason

comes from nickel sulfide inside the glass. Nickel sulfide is a ~Nis in high temperature during the heating section of tempering procedure.

When cooled rapidly in cooling section, there is no enough time for it to turn β-Nis of low temperature. The morphic transformation

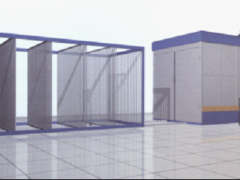

will last for ten of years after the tempering glass is installed. Leading to spontaneous breakage. Heat soak furnace is assistant

equipment to tempering. Upon completion of glass tempering procedure, to avoid breakage happens after installation. This increase the

safety and reliability of building. The machine is characteristic of computer in-process monitoring and controlling, multi curve display,

data storage, record check and curve printing, The machine can be extended to be used in drying low frit heating and pressing of bending lamination

in glass. The machine can be customized.

Dimension of Max. Glass: 5000×2440mm

Glass thickness: 3-30mm

Dimension of furnace: 7200×2280×2800mm

Occupied area: 15000×2300mm

Power: 353KW

Temperature: 0-300 centigrade