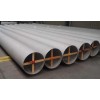

We can divide the welded steel pipe into three main types, the high, the low and the gas tube. Those are evidenced by their different methods. Moreover, we still can see some minority types, such as the furnace pipe.

Making the welded tubes is simpler than other types, like the seamless steel pipes and black steel pipes. Thereby, the manufacturer has high efficiency. Since one hundred year ago, the development of the kind of pipes makes it possible to improve its quality and specifications like the lengths and diameters. Flat products such as plate and sheet are the original materials in making welded tubes. After certain degree compression and temperature, it can make it into desired shape. Basically, manufacturers would like to make it round shape, since it is good for transporting, especially for those low-temperature liquid. Once this outer shape is made, weld joint are used to combine each part together. High energy are needed at the same time, since this process need power to squeeze and form. Customers and buyers are provided more choices as the increasing number of pipes. According to different making process, this type can be divided into two main forms---the spiral welded pipe and longitudinal pipe. For the advantages, simple procedure is the first one, then various types are the second since customers can choose their specific types. What's more, equipment investment is quite low, while the general strength less than seamless steel tubes.