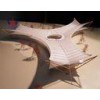

Eco High-tech Tarp Tensioned Membrane Structures Architecturer

Tensioned Membrane Structures General Description

Tensioned Membrane Structures used as shade or cover that shelter from rain and sunshien, even dusty. Matrix Sturcture translateTensioned Membrane Structures into a whole new level of architecture that its excellent performance of lightweight and freeform design do away with conventional building.

The Tensioned Membrane Structures that incorporating new architectual technology is the most suitable building material for building. First, nominally we can design any form for your structures, and it will be an iconic and unique structure or feature for any building, city or even region. Secondly, Tensioned Membrane Structures is a cost effective solution to large span roofing building because of its lightweight, that enable long spans available. What is more, membrane material is eco-material that allows lot of the visible light get through but prevent most UVA and harmful light. In daylight, Membranes 20% light transmittance offers diffused naturally lit spaces by reducing interior lighting costs, at night, the artificial lighting creates an ambient exterior effect.

Compare to conventional building, Membrane Structures requires less maintenance because of its self-cleaning property. The durability and longevity of tensile membrane structures have proven its outstanding quality by building in climates ranging from the frigid artic to the scorching desert heat.

.

Feature of Steel frame

| Steel Code | Size | Chemical Component | Elongation | Yield Point | Tensile Breaking Strength | ||||

| Q253 | (mm) | C% | Si% | Mn% | P% | S% | δ% | Mpa | Mpa |

| Q253B | 114*3 | 0.15 | 0.15 | 0.37 | 0.016 | 0.018 | 26 | 290 | 390 |

| Q253B | 89*3 | 0.13 | 0.14 | 0.37 | 0.022 | 0.024 | 27 | 295 | 375 |

| Q253B | 140*5 | 0.14 | 0.15 | 0.41 | 0.022 | 0.022 | 28 | 285 | 380 |

| Q253B | 219*7 | 0.16 | 0.12 | 0.36 | 0.018 | 0.024 | 25 | 285 | 385 |

| Q253B | 87*4 | 0.13 | 0.16 | 0.36 | 0.018 | 0.022 | 26 | 290 | 385 |

| Q253B | 60*3 | 0.12 | 0.16 | 0.42 | 0.018 | 0.020 | 26 | 280 | 380 |

PVDF Sail Character

| Property | Date | Standard |

| Basic Fabric | Hight Strength Low Yarn Polyester Yarn | DIN EN 60001 |

| Yarn Count(yarn/cn) | 1100 dtex | DIN ISO 2060 |

| Basical Fabric Weight | >100 g/m2 | |

| Weave Style | 12/12/yarn/cm | DIN EN 1049-2 |

| Adhesion | >120N/5cm | IVK 3.13 |

| Total Weight | 1000 g/m2 | |

| Total Thickness | 0.8 mm | |

| Threshold Temperature | (-30-+70) | DIN EN 1876-1 |

| Light Transmission | 20% | |

| Tensile Strength | 4400/4200 N/5cm | DIN EN 1421 |

| Tear Strength | 600/550N | DIN 53363 |

| Acoustical Weakening Index | 15dBA | |

| Surface Treatment | Double PVC Coating | |

| Flame Retardancy | DIN 4102B1, GB8624 B1 | |

| Quality Standard | DINEN ISO9001 |

Clear Photos for Tensioned Membrane Structures

Matrix Structure Company Profile

Matrix Structure is specializing in the design of custom tensile fabric structures, roof and event tent. Its founder and chief engineer have been in Tensioned Membrane Structure Industry for over 10 years experience of design, engineering and manufacturing of quality tension fabric and tensile membrane structures, we aim to provide the highest quality, most cost effective products possible with a customer service experience second to none.

Please feel free to contact us, we will turn your design concepts into reality.