Usage:Tube for conveying gas, water, and oil in both and natural gas industries etc.

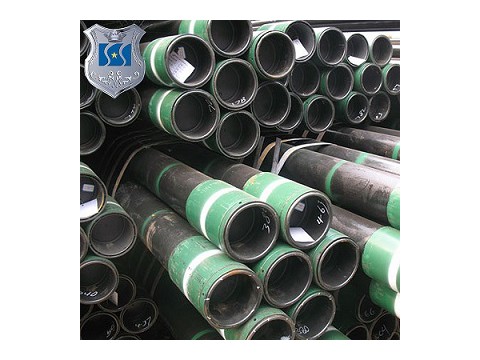

Casing:Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.It is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and to allow drilling fluid to circulate and extraction to take place. Steel Casing Pipes have smooth wall & minimum yield strength of 35,000 psi.

Tubing: Tubing is pipe used for the transportation of crude oil and natural gas from an oil or gas layer to the surface after drilling is complete. It is made to withstand the pressure generated from the extraction process. Tubing is manufactured in the same way as casing, except that an additional process known as "upsetting" is applied to thicken the pipes.

Quality Standard:

SY/T 6194 Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells

API 5CT CASING AND TUBING

BS EN ISO 11960 Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells

NF M87-207 Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells

JIS G3439 SEAMLESS STEEL OIL WELL CASING, TUBING AND DRILL PIPE

IS : 4270Steel tubes for well spainend casing pipes

Steel Grade:H-40, J55, K-55, N-80, C-75, L-80, C-90, T-95, Q-125

Process: ERW and Seamless

Size:

Outer Diameter:Casing: OD 4 1/2"- 20" (114.3mm-508mm)

Tubing: OD 2 3/8" - 4 1/2" (60.3mm-114.30mm)

Wall Thickness: 0. 205"- 0.635"

Length: R1(4.88mtr-7.62mtr), R2(7.62mtr-10.36mtr), R3(10.36mtr or longer)

Connection: Casing: LTC, STC, BTC, VAM.Tubing: NUE, EUE.

End: Beveled, Square cut. And pipe protection cap specially for casing and tubing.

Surface: Corrosion proofing water based paint

Heat treatment: Normalized, Quencher+Temper

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield

strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection, Nondestructive Test (Ultrasonic flaw detector, Eddy current flaw detector), Hydrostatic Test.

Mill Test Certificate: EN 10204/3.1B