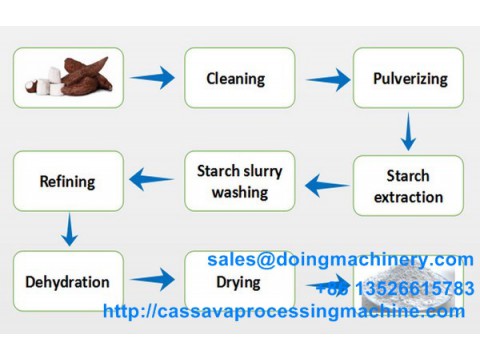

Tapioca flour making process

1. Cassava choosing unit

The quality of the raw cassava has an important influence on the starch quality, therefore the cassava choosing process is the first step towards a high quality cassava starch product. If the chosen cassava is less than 10 months, the cassava starch extraction rate will be very low. While the cassava more than 24 months old cassava has been qualitative which caused great difficulties to broken and grinding. Thus it not only resulted in the reduction of the extraction rate but also increase the cost which is also not a good choice. Therefore it will be better to choose raw cassava between 10-12 month.

2. Cassava cleaning and washing unit

The weighted cassava is transported in dry sieve by conveyor to remove the sand, weed, stones and other debris. There is no water needed in this process for how to make tapioca flour from cassava. The dry sieve is designed with multi spirals which push cassava forward during the cleaning process. Then it goes into the paddle washing machine to further wash the attached silt, grave and other impurities.

3. Cassava grinding unit

The washed cassava is then transported into grinding machine by screw feeder. This is the vital process for how to make tapioca flour from cassava. The purpose of this process is to grind cassava into starch so as to releasse starch from cell wall. DOING rasper is a high efficient machine with a breakage rate more than 94%.

Cassava grinding machine

The grinded cassava slurry then enters into centrifuge sieve for separating fiber and starch. The purpose of this process is to separate the fiber and starch slurry. Normally in order to have a better separation effect, this process will repeat four or five times according to different requirements of the different materials.

5. Concentration and refining unit

After desanding, the cassava starch enters into hydrocyclone station. This process is mainly used for separate the fiber, protein and cell sap from starch for how to make tapioca flour from cassava. DOING full hydrocyclone unit can achieve the concentration, recycling and refining of cassava milk.

Tapioca flour refining machine

The widely used machine for the dewatering process for how to make tapioca flour from cassava is vacuum filter whose main function is to reduce the water content of starch milk. It is required that the moisture content of starch milk is about 38% after dewatering.

8. Drying and packing unit

The dewatered starch is sent to the flash dryer through the screw conveyor for drying for how to make tapioca flour from cassava. Flash dryer utilizes high speed air to dry cassava starch in a few seconds. It is required that the moisture content of starch after drying is between 12% and 14%, reaching the standard of finished products. And then pack the finished cassava starch for packing.

Tapioca flour drying machine

Inquiry: http://services.doinggroup.com.cn/kf.php?mod=client&cid=doingequipment&wid=23

Click here to give you the best price

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: market@doingmachinery.com

market@doinggroup.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

View more:

cassava starch machine

potato starch processing machine