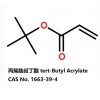

Substance: TBA - tert-Butyl acrylate

Other name: Octa-(O-cyanoethyl)sucrose; 2,2,3,3,4,4,5,5-Octafluorohexanedioic Acid, Dimethyl Ester

1. Physical and chemical properties

Product name: tert-Butyl acrylate

CAS No.: 1663-39-4

Molecular Formula: C7H12O2

Molecular Weight: 128.17

Appearance form: colorless, clear,

liquid

Melting/freezing point: - 69 ℃

Boiling point: 121 ℃(1.013

bar)

Flash point: 17 ℃(closed

cup)

Density: 0.875 g/cm3(25 ℃)

UN No.: 1993

2. Parameters

index

Purity, (GC) ≥ 99.5%

Water Content ≤ 0.04 %

Acidity, (as Acrylic Acid) ≤ 0.1 %

Colour on despatch /(Pt-Co) ≤ 10

Standard Stabilization(MEHQ), 15±5 ppm

3. Package

information:

Big Barrel: 880kg per barrel

Small Barrel: 180kg per

barrel

Tank: 20 ton per tank

4. Applications

tert-Butyl acrylate forms

homopolymers and copolymers. Copolymers of tert-butyl acrylate can be

prepared with acrylic acid and its salts, amides and esters, and with

methacrylates, acrylonitrile, maleic acid esters, vinyl acetate, vinyl

chloride, vinylidene chloride, styrene, butadiene, unsaturated polyesters and

drying oils, etc. tert-Butyl acrylate is

also a very useful feedstock for chemical syntheses, because it readily

undergoes addition reactions with a wide variety of organic and inorganic

compounds.

5. Safety

A

Material Safety Data Sheet has been compiled for tert-butyl

acrylate that contains up-to-date information on all questions relevant to

safety.

6. Storage and

handling

In order to prevent

polymerization, tertiary butyl acrylate must always be stored under air, and

never under inert gases. The presence of oxygen is required for the stabilizer

to function effectively. It has to contain a stabilizer and the storage temperature

must not exceed 35 ℃。Under

these conditions, a storage stability of one year can be expected. In order to

minimize the likelihood of over storage, the storage procedure should strictly

follow the “first-in-first-out” principle. Storage tanks and pipes should be

made of stainless steel or aluminum. Although tertiary butyl acrylate does not

corrode carbon steel, there is a risk of contamination if corrosion does occur.

Regulations for the storage of flammable liquids must be observed

(explosion-proof electrical equipment, vented tanks with flame arresters etc.).

Storage tanks, pumps and pipes must be earthed.

7.

Note

The

data contained in this publication are based on our current knowledge and

experience. In view of the many factors that may affect processing and

application of our product, these data do not relieve processors from carrying

out their own investigations and tests; neither do these data imply any

guarantee of certain properties, nor the suitability of the product for a

specific purpose. Any descriptions, drawings, photographs, data, proportions,

weights etc. given herein may change without prior information and do not

constitute the agreed contractual quality of the product. It is the

responsibility of the recipient of our products to ensure that any proprietary

rights and existing laws and

legislation are observed.