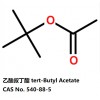

Substance: TBAc - tert-Butyl acetate 540-88-5

Other name: Acetic acid tert-butyl ester

1. Physical and chemical properties

Product name: tert-Butyl acetate

CAS No.: 540-88-5

Molecular Formula: C6H12O2

Molecular Weight: 116.16

Appearance form: colorless, clear,

liquid

Melting/Freezing point: 62℃

Boiling point: 98℃

Flash point: 4.4℃(closed cup)

Density: 0.866 g/cm3(20℃)

UN No.: 1123

2.

Parameters index

Purity, (GC) ≥ 99.5%

Water Content ≤ 0.05 %

Acidity, (as Acetic Acid) ≤ 0.1 %

Colour on despatch /(Pt-Co) ≤ 10

3. Applications

TBAc solvent is a

VOC(volatile organic compound)-exempt, non-HAP(hazardous air pollutant),

urethane-grade solvent with low toxicity, It has excellent solvency for a variety

of substances including nitrocellulose, acrylic, alkyd, polyester and urethane

resins. TBAc solvent is substitute for variety of HAP and VOC solvents

including toluene, xylene, esters, ketones and hydrocarbons.

Coatings, Inks, Adhesives: TBAc solvent finds use in decorative and industrial coating formulations, packaging inks and pressure-sensitive adhesives. It is a useful tool in the formulation of VOC-and HAP-compliant coatings, inks and adhesives. TBAc solvent is less volatile and flammable than exempt acetone and methyl acetate

TBAc solvent has similar evaporation rate and solvency as MEK,MIBK, ethyl and propyl acetate, and toluene in a variety of coating systems, including 2K urethanes, acrylics, nitrocellulose lacquers and baking enamels. Because of its superior resistance to amines, TBAc solvent can also be used in epoxy polyamide coatings as replacement for toluene.

Cleaners: For solvent-based cleaning, including metal degreasing and specialized equipment cleansing, TBAc solvent improves the cleaning efficiency of toluene, mineral spirits and acetone on baked-on greasy soil and lithium grease. TBAc solvent is non-halogenated and cannot deplete the ozone layer. TBAc solvent shows very broad solvency. Its solvency characteristics generally match those of chlorinated solvents and hydrocarbons.

Electronics: Another area where TBAc solvent may replace other solvents is in photoresist formulations used in semiconductor processing. In these processes, it is used in positive photoresist formulations. TBAc solvent may also be used in solvent systems for cleaning and degreasing circuit boards and removing solder flux.

Other Applications: The properties listed in the previous section also support the use of TBAc solvent in agricultural and textile products. It is useful intermediate in the pharmaceutical industry.

4. Storage and

handling

Storage condition:

Keep container closed. Store in a cool, dark, well ventilated place. Store must be locked. Keep away from incompatible materials such as oxidizer storage.

Handling measures:

Good ventilation in the treatment. Wear suitable protective equipment. Smoke prevention. Keep away from heat / sparks / fire / hot surfaces. Prohibit smoking。 Take measures to prevent the accumulation of static electricity. Use explosion-proof equipment. Thoroughly wash hands and face after treatment.

5. Note

The data contained in

this publication are based on our current knowledge and experience. In view of

the many factors that may affect processing and application of our product,

these data do not relieve processors from carrying out their own investigations

and tests; neither do these data imply any guarantee of certain properties, nor

the suitability of the product for a specific purpose. Any descriptions,

drawings, photographs, data, proportions, weights etc. given herein may change

without prior information and do not constitute the agreed contractual quality

of the product. It is the responsibility of the recipient of our products to

ensure that any proprietary

rights and existing laws and

legislation are observed.

tert-Butyl Acetate Cleaning Solvent is the

most effective solvent for cleaning polished metals without dulling the

polished surface.

This solvent is recommended for cleaning and removal of oils, polishing rouge

and contaminants from a metal substrate prior to coating with Cerakote Clear

Coatings.

Liberally and repeatedly flood the substrate with tert-butyl acetate

and then wipe with a clean lint-free, micro fiber rag. This process should be

repeated, flooding the surface with tert-butyl acetate and then wiping with a

clean lint free, micro fiber rag, until no residue is observed on rag.

This product is VOC exempt and is shipped in gallon quantities.