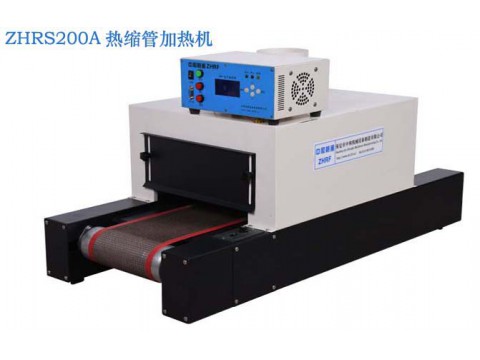

ZHRS200A,一款智能温度调节单面热缩管加热器(智能数字温控,采用液晶屏显示工作状态,独立控制系统)适用于线束加工企业热缩管的加热收缩,调节温度根据生产工艺要求,收缩时间短,可以热收缩管任意长度,可以连续工作24小时不间断,里面有全向反射热材料,使热缩管被均匀加热。

适用于:

1. Connection and contraction of PE heat shrinkable tube, PVC heat shrinkable tube and double wall heat shrinkable tube with glue.

2. Thermal shrinkage of PVC pipe.

3. Thermal contraction of capacitors, batteries, wire terminals, heat shrinkable sleeves / membranes, etc.

Characteristics:

Equipment composition

Transmission system + heating system + control system

Heat insulation design of heating zone

The shell of the heating area is designed with double layer heat insulation, which makes the inside and outside temperature separate, that is to save energy and protect the working environment.

Omni-directional heat reflecting inner wall

The heat reflecting inner wall in the heating box ensures the uniform heating effect of the heating.

Adjustable import and export height

The conveyor belt heating box is completely closed, the input and output end of the heating box has a sliding door that can rise and fall, effectively prevent the heat source from leakage, protect the working environment, energy conservation, and increase the machine's ability to use one machine in many different jobs.

Adjustable infrared heating pipe height

The infrared heating tube can adjust the height quickly. Ensure repeatability of distance between light source and conveyor belt.

Intelligent control system

LCD

Deviced friendly man-machine interface, menu operation of liquid crystal Chinese characters,simple and convenient manipulation,Real-time display of work status.

Open machine presupposition function

The machine can set the output temperature, the working time, etc.

Intelligent power regulation

According to the seted up temperature, the heating system intelligently recognizes the output power, and the output is stable.

Temperature control system

The power output is controlled by digital stepless mediation, the temperature is controlled, the output is stable, and the precision of temperature control is 2.

Parameter memory function

The power, the temperature, the working hours and other parameters of the hot air fan have memory function.

|

classification |

Item |

parameter |

|

Size |

Overall machine size(L×W×H) |

1000×460×465mm |

|

Control power(L×W×H) |

200×150×200mm |

|

|

Heating area(L×W) |

520×460mm |

|

|

Belt width |

200mm |

|

|

Maximum transmission width |

250mm |

|

|

最大传输高度 |

100mm (可调) |

|

|

输送带 |

材质 |

特富龙 |

|

速度 |

0.5〜3米/分钟 |

|

|

电机的力量 |

25W (无级调速) |

|

|

加热管 |

加热管名称 |

红外线加热管 |

|

加热管电源 |

300W ,6个分支机构 |

|

|

加热方向 |

自上而下,单面加热 |

|

|

温度 |

温度准确度 |

± 2 ℃ |

|

最高温度 |

> 200 ℃ |

|

|

电源 |

电力需求 |

220V 两件 |

|

功率 |

1860W |