Choosing and weighting-cleaning and washing-cutting and crushing-separating-concentration and refining-dewatering-drying and packing

1.Choosing and weighting of sweet potato

The quality of sweet potato starch is determined by the raw sweet potatoes. Therefore we need to choose high quality sweet potato without damage for isolation of starch from sweet potato. Then the chosen sweet potatoes are weighed and stored in a sweet potato stack. After that, they are transported by a conveyor to a cleaning machine for processing.

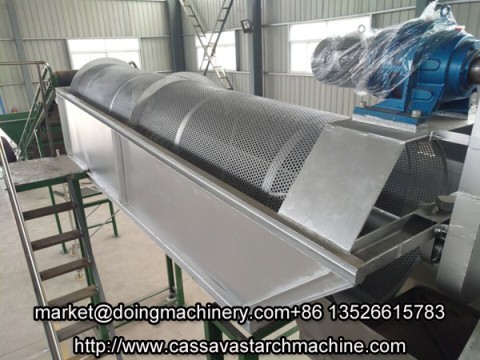

Sweet potato washing machine

For the process of isolation of starch from sweet potato , the main purpose of this process is to remove the sediment from the outer cortex of sweet potatoes and wash the epidermis of sweet potatoes. The fresh sweet potato is cleaned in dry sieve in which the impurities are cleaned such as sand and small stones. Then we use the rotary washing machine for removing the soil, sand and other impurities. This process is the basis of guarantee the quality of starch, the cleaner the raw sweet potatoes are cleaned, the better the starch quality is.

3.Cutting and crushing process

Due to the size of the sweet potato, it need to be cut into small pieces before crushing so that the crushing process can be easier. Crushing is a vital process for isolation of starch from sweet potato because it determines the extraction rate of starch. Doing Company independent research and development of high efficient crusher which can obtain higher percentage of free starch. After crushing, the sweet potato is crushed into starch slurry.

4. Separating process

The crushed sweet potato paste contains other impurities like fiber, protein and cell sap. Therefore the separating process is needed. It also has an important influence on the starch yield. For the process of isolation of starch from sweet potato , we use centrifuge sieve for separating fiber out of starch. Professional sweet potato starch processing plant use multiple-stage centrifugal process to improve the separating effect.

Sweet potato starch separating machine

This process is for the concentration, recycling and refining of the starch milk. To ensure a better washing effect, DOING isolation of starch from sweet potato process adopts 13-stage hydrocyclone station which can better remove the impurities of fiber, protein and other impurities contained in the starch milk. In this way, all the indicators of starch produced can be guaranteed to meet the standards.

6. Dewatering process

The dewatering process is mainly for reduce the water content of the wet starch for isolation of starch from sweet potato. By adopting negative press principle, vacuum filter can effectively reduce the water content of starch so that it can be dried in the flash dryer. After dewatering, the water content of starch milk first should be about 38%-40%.

Sweet potato starch drying machine

Then it is the drying and packing process. For the process of isolation of starch from sweet potato , factory usually use flash dryer for drying of starch. The high speed hot air fully mixed with wet starch, by heat exchanging, the wet starch is dried. The whole drying process is completed in an instant. After that, the collected starch is packed into 25kg or 50kg finished products.

Click here to give you the best price

Contact us(inquiry)

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: market@doinggroup.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

View more:

http://www.starchprojectsolution.com

cassava starch machine