Product Description

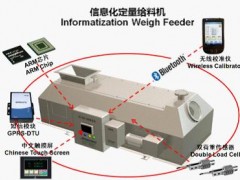

Informatization Weigh Feeder System is a set of complete system equipment for continuous conveying, dynamic weighing and feeding control of granular and lump material on real-time. Informatization weigh feeder is a new generation intelligent product of traditional weigh feeder, which applies modern information technology to automation control system to realize the continuous weighing and control of granular material and bulk material. The control system has the characteristic of high degree informatization and can achieve production modernization and comprehensive production management through humanized operation.

Product Feature

1. With the functions of message notification and alarm, and can bind more than one user’ mobile phone numbers (such as directors and professional engineers, etc.), as long as the mobile network can reach any place, users can receive the information of production and equipment operation at anytime, anywhere without standing near the equipment control system. On the one hand, the engineers can trace the production condition, improve product quality and prevent the production of substandard products; On the other hand, it is convenient for the management personnel to record the production information, manage the production and performance evaluation. At the same time informatization weigh feeder can inform its working condition to the management personnel so as to reduce the management fees and the manpower and material resources.

2. Commissioning and calibration adopts wireless hand-held equipment with friendly interface and easy operation. Because the user can carry the wireless calibrator so it is very convenient for them to know the field condition so as to reduce the safety accident during the start and stop of the equipment. Particularly in the dosing field when there are several weigh feeders with the same type running at the same time, the user can operate the wireless hand-held equipment to read and write the parameters of these same weigh feeders at the same time, so as to greatly reduce the workload of user to debug several equipments.

3. Weight feeder connected with DCS and the frequency converter through 485 bus. Using Modbus communication protocol makes the connection simple. Only two communication lines can finish the information exchange accurately so as to reduce the investment cost of the equipment greatly, meanwhile, convenient for field wiring arrangement.

4. For weighing and measurement, it adopts double load cell and direct gravimetric structure with the characteristics of simple structure, easy to install, easy to maintenance, little interference for load cell, no pivot and additional weight which makes the whole weighing device more stable and reliable, the measurement more accuracy. The weighing device adopts spill-proof design to reduce the impact of accumulated material on the equipment.

5. For mechanical structure, the design is more flexible. Such dust-proof device as cover plate, head cover, and tail cover, dust collecting pipe can be separately added according to material performance. working hole and inspection window in the front and back of the feeder are equipped to inspect the material operation situation and adjust the belt take-up.

6. The feeder has been equipped with automatic compensation cleaner to avoid the trouble of manual adjustment after the wear of the cleaner.

7. Processor of the control system adopts 32-bit ARM chip. Comparing with the traditional controller, it is greatly improved whether in instruction throughput or computing capacity, so it can greatly improve measurement and control accuracy.

8. Touch screen human-computer interface is user-friendly, so user can operate the weigh feeder without remembering lots of parameter codes so as to save the training cost.