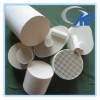

Ceramic saddle is improved from the arc saddle, Ceramic saddle changes the both arched surface torectangular surface and makes the interior radius of curvature different, this construction overcomes the problem of nesting basically, Ceramic saddle makes porosity distributed even and improves the distribution of the fluid, greater capacity and lower pressrue drop than Rasching ring.

Chemical analysis.

| SiO2 |

>73% |

| Al2O3 |

17-25% |

| Fe2O3 |

<1.0% |

| CaO |

<0.5% |

| MgO |

<0.5% |

| K2O+Na2O |

2-4% |

| Other |

<0.1% |

Physical properties

| Nominal size(inch) |

3/8'' |

1/2'' |

5/8'' |

3/4'' |

1'' |

1.5'' |

2'' |

3'' |

| Width(mm) |

8 |

10 |

12 |

14 |

21 |

30 |

40 |

57 |

| Height(mm) |

8 |

10 |

12 |

14 |

19 |

30 |

40 |

57 |

| Length(mm) |

16 |

20 |

24 |

28 |

38 |

60 |

80 |

114 |

| Thickness(mm) |

2 |

2.5 |

2.5 |

3 |

4 |

4.5 |

5.5 |

9 |

| Number per m3 |

1560K |

610K |

269K |

146K |

59K |

19680 |

8243 |

2400 |

| Remarks |

K represents 1000 pieces |

| Package density (kg/m3) |

900 |

780 |

700 |

670 |

650 |

580 |

550 |

530 |

| Free volume (%) |

63 |

68 |

71 |

75 |

77 |

80 |

79 |

75 |

| Surface area (m2/m3) |

825 |

647 |

535 |

350 |

254 |

180 |

120 |

91 |

| Specific gravity (g/cm3) |

2.25~2.35 |

| Water absorption(%) |

<0.3 |

| Acid resistance (%) |

>99.6 |

| Max operating temp. |

1100°C |

| Porosity (%) |

<1 |

| Moh’s hardness (scale) |

>6.5 |

| Thermal conductivity(w/m.k) |

0.9-1.0 |

| Specific heat (j/kg°C) |

850-900 |

Dimension

Nominal

Size |

Alias

DN |

Diameter of Deck

D |

Outside Diameter

L |

Height

H |

Wall thickness

T |

Width

W |

| 3/8'' |

10 |

10±2.0 |

16±2.0 |

8±2.0 |

1.5±1.0 |

8±2.0 |

| 1/2'' |

12 |

12±1.0 |

20±1.4 |

10±1.0 |

2.0±1.0 |

10±2.0 |

| 5/8'' |

16 |

16±2.0 |

24±1.5 |

12±1.0 |

2.0±1.0 |

12±2.0 |

| 3/4'' |

19 |

19±5.0 |

28±5.0 |

20±3.0 |

3.0±1.0 |

20±3.0 |

| 1'' |

25 |

25±4.0 |

38±4.0 |

22±3.0 |

3.5±1.0 |

22±2.0 |

| 1.5'' |

38 |

38±4.0 |

60±4.0 |

35±5.0 |

4.0±1.5 |

35±5.0 |

| 2'' |

50 |

50±6.0 |

80±6.0 |

48±5.0 |

5.0±1.5 |

40±4.0 |

| 3'' |

76 |

76±8.0 |

114±8.0 |

60±6.0 |

9.0±1.5 |