Details

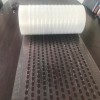

MLLDPE air flow ventilated pallet wrap film requires the following three models:

1): 1200 meters X 50 cm x 30 um (machine ),

Technical parameters:

Pre-stretching rate: 230%

Average thickness: 30um +/-3um

Width: 500mm +/-5%

Damage stretch rate: 250% +/-15%

Damage tension: 26kg +/-15%

Number of holes: 13

Weight per meter: 10.11g +/-10%

Net weight per roll: 12.132kg +/-10%

Packing: 40 rolls per pallet (2 layers x 20 rolls), 42 pallets / 40 feet container, a total of 1680 rolls (20.38 tons) / 40 feet high container.

2): 4000 m X42 cm x 9um, net weight per roll: 17.92kg +/-10% (machine )

Technical Parameters:

Pre-stretching rate: 65 %

Average thickness: 9um+/-3um

Width: 420mm+/-5%

Damage elongation: 75% +/-15%

Damage tension: 50kg +/-15%

Number of holes: 13

Weight per meter: 4.48g +/-10%

Packing: 32 rolls / pallet(2 layers x 16 rolls), 42 pallets/ 40 feet container, 1344 rolls(24.08 tons) / 40 feet high container

3): 500 m X 42 cm x 9 um, net weight per roll: 2.24 kg +/- 10% (manual )

Technical Parameters:

Pre-stretching rate: 65 %

Average thickness: 9um+/-3um

Width: 420mm+/-5%

Damage elongation: 75% +/-15%

Damage tension: 50kg +/-15%

Number of holes: 13

Weight per meter: 4.48g +/-10%

6 rolls (13.44kg) / CTN, 24 CTNS / pallet, carton: 57x38x31cm, 144 rolls / pallet, 42 pallets / 40HQ., 6048 rolls (1008 CTNS, 13.55 ton) / 40 HQ

Characterise:

1.Less material use for wrapping a load when compared to the alternative solutions.

2.Eliminates condensation and mold formation.

3.Suitable for light or heavy loads.

4.Requies less films to stabilise the pallets .

5.quicker and easier to apply than corner boards and straps.

6. Low weight ,but high elasticity .