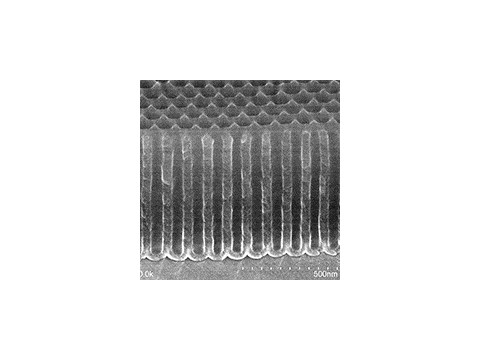

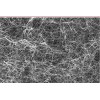

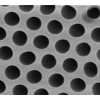

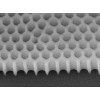

Innovation is the cornerstones of Shenzhen Topology Precision Film Technology Co., Ltd.s success. In the future, Topological fine film also hope to continue to innovate, for the majority of customers to provide anodic aluminum oxideservice. Over the years, Topological fine film always believe that only adhere to innovation and professional, in order to better meet customer demand for evaluation of high porous anodic alumina. details:4.The main properties of anodic aluminum oxide: anodizing can significantly improve the corrosion resistance of aluminum alloy, improve the surface hardness and wear resistance of aluminum alloy, and have good decorative properties after proper coloring treatment. Aluminum and its alloy anodic aluminum oxide coloring technology can be divided into three types: chemical dyeing, electrolytic coloring and electrolytic overall coloring. Chemical dyeing uses the porosity and chemical activity of the oxide film layer to adsorb various pigments to color the oxide film. According to the coloring mechanism and process, it can be divided into organic dye coloring, inorganic dye coloring, color paste printing, color dyeing and achromatic dyeing. Wait. Electrolytic coloring is the electrode electrolysis of aluminum and its alloy in an aqueous solution containing a metal salt, depositing a metal, a metal oxide or a metal compound at the bottom of the porous layer of the aluminum oxide, due to the scattering of light by the electrodeposit And present a variety of colors. Electrolytic overall coloring means that aluminum and its alloys are colored while anodizing, which is characterized by oxidation and coloring in one step, and the colored film has good light resistance, heat resistance, corrosion resistance and wear resistance.