I. The technical flow of the production line

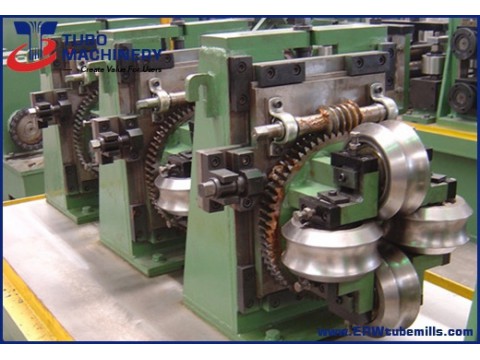

{SteelTape}→Double-head un-coiler→Automatic Strip-head Cutter and welder→Accumulator→Forming section (Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller) + De-burr frame→Cooling unit→Sizing unit and straightener→Flying saw under computer-control→Run-out table

II. Basic conditions:

| 1. Production Capacity | |

| Round Pipe | 25mm - 76.2mm |

| Square & Rectangular | 20*20 - 60*60(40*80)mm |

| Wall Thickness |

0.8 - 4.0mm (Round Pipe); 0.8 - 3.0mm(Square Pipe) |

| Speed | Max.100mm |

| Pipe Length | 4m – 12m |

| 2. Steel Strip Specification | |

| Material | Low Carbon Steel, Q235, Q195 |

| Coil I.D. | 460 - 510MM |

| Coil O.D. | Max. 1800mm |

| Strip Width | 80mm – 240mm |

| Strip Thickness | 0.8mm – 4.0mm |

| Max. Weight | 3500kgs |

| 3. Electricity | |

| Dynamic power: | 380V, 3 phases, 50Hz (Depending On Local) |

| Control Power: | 220V, one phase, 50 Hz |

| 4. Solid State High Frequency Welder: 250KW | |

| 5. Electric installed capacity: Appro. 500KW | |

| 6. Cooling Water | |

| Reservoir for High Frequency equipment: | 25m³, one set |

| Reservoir for circulating cooling water: | 25m³, one set |

| 7. Compressed Air | |

| Pressure | 0.5 MPA |

| Flow | 0.8m3/hour |

| 8. Line Speed: Max.100m/min | |

| 9. Size of Whole Line: 65m X 6m (Length X Width) | |

We always design and make each line according to each customer's specific requirements, so each customer can buy his own well-content line from us.

For more information, please send us inquiry.

Contact :Andy

Email :andy@erwtubemills.com

Web: www.pipemakingmachines.com

Mob/whatsapp:8615631120280