|

APPLICATION (CALCIUM SILICON) |

|

|

|

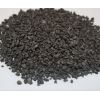

Calcium Silicon is a potent deoxidizer and desulfurizer utilized in the production of high grade steels. Although Silicon itself is a powerful deoxidizer, Calcium is by far more powerful. In addition, Calcium

Silicon is used to control the shape, size and distribution of oxide and sulfide inclusions improving fluidity, machinability, ductility, and impact properties of the final product.

for the purpose of coating the inside of each mono cast machine. steel applications is in the form of cored wire. This is mainly because calcium has a low density and high reactivity in the ladle making it difficult to introduce and retain in the melt. Cored wire eliminates these variables.

|

|

CALCIUM SILICON (CaSi) |

||||

|

SPECIFICATION |

Ca (min) |

25% |

28% |

30% |

|

Si (min) |

58% |

58% |

58% |

|

|

C (max) |

1.0% |

1.0% |

1.0% |

|

|

S (max) |

0.06% |

0.06% |

0.06% |

|

|

P (max) |

0.06% |

0.06% |

0.06% |

|

|

Al (max) |

2.0% |

2.0% |

2.0% |

|

|

Size: 0-1.6mm; 0-2mm; 2-10mm; 10-50mm; 10-100mm; 10-200mm; Packing: in 1MT big bag |

||||