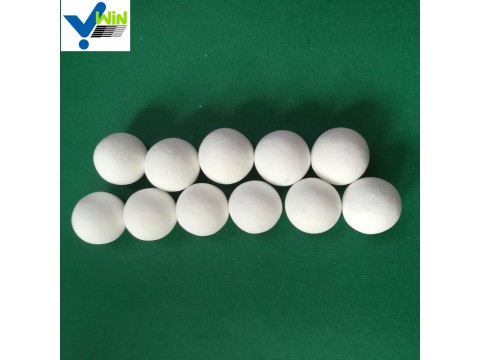

Size: 3,6, 8,9, 10,13,16,19,25,30,32,38,50,65,70,75,100

Chemical composition and physical properties

|

Chemical composition |

Al2O3(%) |

92 |

95 |

99 |

|

Fe2O3(%) |

≤0.4 |

≤0.3 |

≤0.1 |

|

|

The remaining ingredients can be determined by negotiation between the supplier and the buyer as necessary. |

||||

|

Water absorptivity (%) |

3±1.Can also be negotiated

|

|||

|

Proportion(kg/m³) |

≥3.1 |

≥3.2 |

≥3.4 |

|

|

Bulk density(kg/m³) |

1700-1950 |

1800-1950 |

≥1900 |

|

|

Dust, cracking or breaking |

Single bag less than 5%

|

|||

|

Size deviation

|

Uniform sphere, the ratio of the maximum and minimum diameter of a porcelain ball does not exceed 1.2

|

|||

|

Load softening(yb/t370-1995) |

Less than 0.6% deformation under 0.2 Mpa |

|||

|

Thermal shock resistance (yb/t376.2-1995) |

1200℃ reduced to 600℃, 10 times no cracks on the surface |

|||

|

Reheating heat change (gb/t3997.1-1998) |

1400℃ for 12 hours with a maximum of 0.25% and an average of less tahn 0.20% |

|||

|

Dimensional tolerance

|

≤10mm |

±1.0 |

||

|

11—25mm |

±1.5 |

|||

|

26—50mm |

±2.0 |

|||

|

≥50mm |

±3.0 |

|||

|

Free fall strength |

Lossless rate≥99% |

|||