WLRS2060-2continuous heat shrinkage tube heater, local heating does not damage the wire, can be placed on the worktable, especially suitable for processing short wire harness, 24 hours continuous work, double-sided heat shrinkage tube heater, double-sided heating temperature controllable, single and double-sided heating optional, heating zone location adjustable, heating width optional.Omni-directional heat-back material makes the heat-shrinkable pipe uniform, heating temperature, conveying speed, unlimited adjustment, suitable for a variety of small wiring harness.

Characteristic:

Equipment composition

Heating system + conveying system + cooling system + control system

One side or double side heating is optional

According to the heating requirements of the heat shrinkable tube, it is free to choose one side or two side heating.

The width of heating zone is adjustable

The width of the heating zone can be adjusted by the user according to the size of the heat shrinkable tube, save energy as much as possible and ensure the wire do not be hurt.

Heat insulation design of heating zone

The double shell design of heating area makes the inside and outside temperature separate, that is to save energy and protect the working environment.

|

Classification |

Item |

Parameter |

|

Heater size |

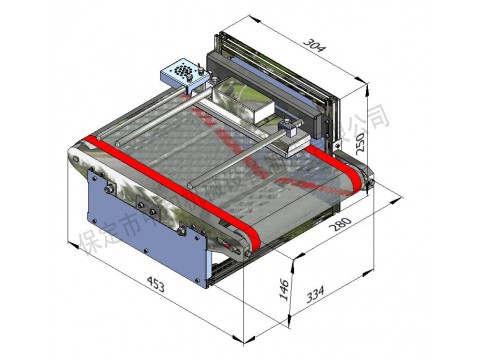

Overall machine size(L×W×H) |

453mm×334mm×250mm |

|

Maximum Machining Wire Harness Diameter |

40mm |

|

|

Maximum heating width |

60mm,(80\120mm optional) |

|

|

Heating length |

240mm |

|

|

Cooling zone |

200mm |

|

|

Maximum conveying width |

225mm |

|

|

Maximum conveying height |

50mm |

|

|

Conveyor belt |

Material |

Teflon |

|

Speed |

1~5m/min |

|

|

Conveyor motor power |

200W(Stepless Speed Regulation) |

|

|

Heating pipe |

Name of heating tube |

Heating porcelain plate |

|

Heating tube power |

1KW,*2 |

|

|

Power supply for heating machine |

Power demand |

220V |

|

Power |

2.4KW |

|

|

Security |

Safety grade |

PE earth wire |

|

Weight |

Net weight |

15KG |