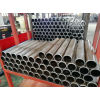

Honed steel tubing is broadly utilized as hydraulic cylinder tubes and pneumatic cylinder tubes in many industries, it is used to produce and repair hydraulic cylinders and pneumatic cylinders.

There are two main manufacturing process for producing Steel honed tubes, which are honing process or skiving & roller burnishing process. The mother tube we usually use "Suitable To Hone" Cold Drawn Seamless Tubes. The process of the honed pipe is determined upon the dimension, mold available and the requirement of the customer. As the professional honed tube factory, we can suggest the better manufacturing process according to the specific condition of the applications.

Materials:

The most popular material of our honed tubes is carbon steel grade SAE 1020. Besides SAE1020, we also produce honed cylinder tubes in other materials such as SAE 1026, E355 and ST52.3, stainless steel 304 /316 and so on.

Size Range:

As one of the leading honed tube manufacturers in China, our factory produce honed cylinder tubes in a wide range of metric sizes and imperial sizes.

Inside Diameter 32mm to 600mm; Imperial sizes equally.

We supply our honed tubing in fixed length and random lengths, the max. Length our our honed tube is 14 meters.

Applications:

Our Honed tubing is mostly applied for making and repairing hydraulic cylinders and pneumatic cylinders, and our honed steel tubing is ready to use as hydraulic cylinder tubes without any further inside diameter machining.

Besides the above, our honed tubes also can be used in other applications where high precise inside diameter dimension is required and high smoothly inside surface is required.