Secondary Belt Cleaner SXBMD-PM

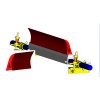

1. The tungsten carbide blade with higher wear resistance and longer service life has a good scraping effect on high temperature or sticky materials;

2. With combined blade design, easier for installation and maintenance. Equipped with rubber buffering device, specialized for noise absorbing, vibration reducing and tensioning. When the blade passes through the rubber patch bump on the belt surface, the elastic tension can be obtained through the rubber buffer device, so that the scraper blade can be attached to the belt surface to continue to work;

3. With spring adjusting seat design, prevented the whole blades from damaging by instantaneous impacts, and easy to be installed and adjusted;

4. Installed on the working surface of the return conveyor belt at the lower part of the head pulley , suitable for two-way running belt;

5. Suitable for the conveyance of all kinds of materials, such as coal, coke, sinter, salt, iron ore and fertilizer, and widely applied in thermal power plants, iron and steel plants, cement plants, fertilizer plants, coking plants, coal cleaning plants, coal mines, petrochemical plants, mining, paper mills, chemical plants, terminal transfer stations and other industries.