Product Introduction

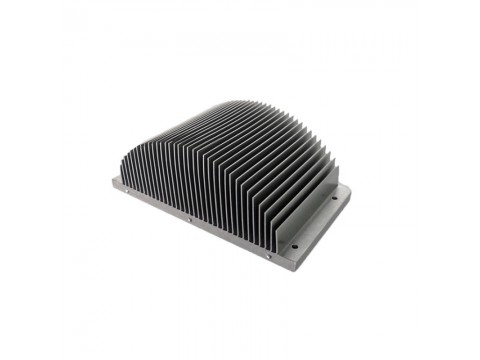

Skived Fin heat sinks can be an alternative to extruded heat sinks when looking for a fin density which can’t be achieved by extrusion technology. Skived heat sinks can be manufactured from either copper or aluminum and usually have 0.5 (0.020”) thick fins.

Design Flowchart

Custom Heat pipe Heat sink, Copper heat sink Supplier, heatsink OEM service.

Technical Parameters

Heatsinks : Alumimum stacked fin +Al CU ba

· High aspect ratio

· Thin fin

· Low tooling cost

· Easy and inexpensive to prototype

· Ideal thermal connectivity with the heat sink base

· Unidirectional flow

· Single piece construction

Skived fin heat sinks are commonly found in the following applications:

Computers and electronic components

Telecommunication equipment

Industrial equipment and components

Lighting lamps and household appliances industry

Automotive components

Pioneer Thermal products mainly include CNC machining, cold forging heatsinks, cold plate, die casting heatsinks, extrusion heatsinks, heatpipe assemblies, skived fin heatsinks, stacked fin heatsinks, folded fin heat sinks

Any heatsinks and skived heatsinks, please contact Pioneer Thermal. We'll reply you within 12 hours.

Email: sales@ptheatsink.com

vivian@ptheatsink.com

Our Customers

Our most of products are customized and widely applied in IPC,server,telecom & communications infrastructure &power,LED lighting,medical equipment and other products.

Shipping Methods

Any cold forging heatsinks services, please contact Pioneer Thermal. We'll reply you within 12 hours.

Help your design design team to improve the part for manufacture.(design refine/process optimize/cost reasonable)