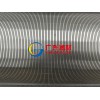

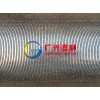

Prepack Well Screens have been used for over 30 years for sand control in Oil wells. Originally used in horizontal wells where gravel packing technology could not place gravel in the horizontal orientation, the prepack screen was the only means to place the sand controlling gravel pack in the well formation. Pack uses two concentric wire wrap screens with the gravel pack contained within the annulus.

Prepack well screen can be used in both Gravel Pack and Stand Alone Screen (direct retention) applications. Used in Gravel Pack completion, Pack provides additional insurance against an incomplete gravel pack and also a very high erosion resistant screen.

Pack uses a Ceramic proppant (although resin coated sand is available upon request) which has three standard size ratings -: 12/18, 16/20 and 20/40. Ceramic proppant has higher permeability due to its rounder, more spherical shape compared to that of resin coated sands. This provides with a lower reduction in well impairment (Skin) compared to conventional Prepack Screens.

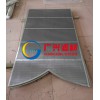

Features

_ Every Wire and Rod intersection is welded with consistent weld integrity

Design

_ Ceramic Proppant with higher permeability

_ Rigorous Quality Control Inspection, 100% insurance against pack voids.

_ NACE Compliant for corrosion resistance

_ Recessed Weld Rings for run-in damage protection

_ Small product OD

_ Options for end and mid joint centeralisers (Spiroliser type or blade)

_ Options for base Pipe Perforation open area.

_ Different metallurgy of base Pipe available.

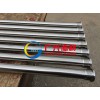

Standard Construction

base Pipe Diameter

base Pipe Weight

Hole diameter

No. Holes per foot

Screen OD

Product Weight

2⅜”

4.6 ppf

⅜”

24

3.22”

8.7 ppf

2⅞”

6.4 ppf

⅜”

36

3.85”

11.1 ppf

3½”

9.2 ppf

½”

36

4.35”

14.3 ppf

4”

9.5 ppf

½”

48

4.85”

15.8 ppf

4½”

11.6 ppf

½”

48

5.35”

18.6 ppf

5”

15 ppf

½”

60

5.86”

22.9 ppf

5½”

17 ppf

½”

72

6.36”

26.0 ppf

6⅝”

24 pff

½”

96

7.48”

34.5 ppf

info9226(a)guangxing-screens(.)com