Doing Company provides two ways to process radiators considering different types of radiators and various capacities: stripping type radiator recycling machine and large-scale radiator recycling machine.

Large-scale radiator recycling machine

Large-scale radiator recycling machine

The first way is using large-scale radiator recycling machine. It has high processing capacity and efficiency. Besides, it can process all kinds of radiators from multi-layer to distorted. As a fully automatic machine, it only requires one to two workers to operate. And only need 4 steps, the copper and aluminum will separate from radiator.

1, Shredding

The shredder will cut the radiator into small pieces, so that the machine can deal with the radiator easily.

2, Crushing

It can crush the radiator pieces into smaller, or can crush these radiator which are not shredded by shredder.

Process of radiator recycling machine

Process of radiator recycling machine

3, Negative pressure baffling and iron removing

This step is aimed at separate light weight aluminum and iron from radiator.

4, Air separation

The air separator will separate aluminum and copper according to their different gravities. Then you will get copper and aluminum out of radiator easily.

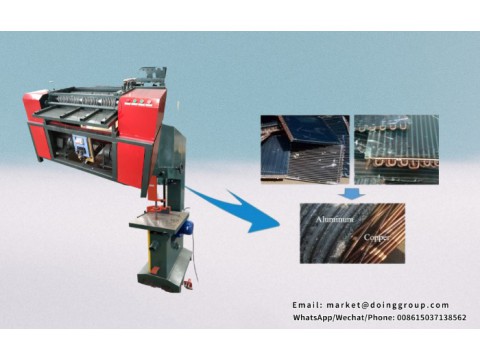

Stripping type radiator recycling machine

Stripping type radiator recycling machine

The other way is using stripping type radiator recycling machine. Compared to large-scale radiator recycling machine, it has some limited. It only can process both single and double layer radiators with the sizes of 19mm, 21mm and 25mm which are complete and flat. This machine is a simple design but high efficient equipment. It only requires one worker to put the radiator on the operating table. once the radiator is put in the machine, copper tubes can be directly stripped off, and thus it can quickly come out with copper tubes and aluminum foil.