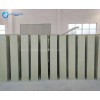

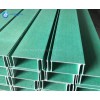

LANDYOUNG FRP板桩 是由无碱玻璃纤维、不饱和聚酯树脂或乙烯基树脂通过拉挤工艺制成的复合材料型材。

说明

LANDYOUNG FRP板桩 是由无碱玻璃纤维、不饱和聚酯树脂或乙烯基树脂通过拉挤工艺制成的复合材料型材。

玻璃钢板桩

应用

玻璃钢板桩应用范围广泛,可用于水利农田建设工程、防灾减灾工程、建筑工程、交通工程、港口工程、市政工程、环保工程、水产养殖、畜牧业、海洋开发和其他领域。

• 海洋舱壁和海堤

• 潮汐墙

• 防波堤

• 码头结构

• 冲刷保护和侵蚀控制

• 挡土墙

• 地下水切断

• 化学遏制

• 流体防渗屏障

• 保护基础结构

• 防洪

• 防洪墙/防洪堤

• 稳定大坝

• 管道保护

• 用于水或废水流量控制的挡板墙

• 河堰

• 池塘衬里

• 农业应用渠道衬里

• 河流改道

• 采矿排水系统

优点和特点

玻璃钢板桩解决了传统钢筋混凝土和钢护岸布局的腐蚀问题,降低了布局的维护成本,增强了布局的耐久性和安全性。

• 成本效益

The real measure of this is not just the comparison of costs for the initial installation; you also need to figure in the costs over the long term. Since FRP sheet piling lasts much longer than more traditional materials, the cost of repairs and replacement is delayed.

• Consistent Appearance

It is well known that wood fades over time. Paint may cover that up, but the paint color will fade as well. There is really not a lot you can do about that except continue to paint in order to keep it looking nice.

FRP sheet piling, on the other hand, holds the same beautiful appearance for a very long time.

UV Resistance

Most materials react negatively to the harmful ultraviolet rays of the sun, and it doesn't take very long for that to start happening. When the time period is stretched out over years, the sun can do some real damage.

FRP sheet piling is designed to be resistant to this, so the effects of the sun are not as serious or as quick.

• Unaffected by Marine Borers

Marine borers are small mollusks or crustaceans that live in the ocean, and their primary source of sustenance is wood. If you use wood for your seawall construction, you will almost immediately have marine borers latching on and drilling into it.

This degrades the integrity and stability of the seawall over time, which defeats the whole purpose of the structure. You want your seawall to be strong enough to withstand very harsh conditions. If a marine borer comes across a seawall constructed with FRP, it just keeps moving. FRP provides no attraction at all for marine borers.

• Easy Installation

FRP sheet piling provides for an easy installation, particularly compared to wood. Wood is subject to imperfections, warping, and various deformities. This can sometimes cause problems or delays at the time of the installation. Unlike wood, FRP sheet piling does not grow in nature; the components of a vinyl seawall are manufactured to some very strict and precise standards. There is virtually no room for error, so you are able to have a consistent product each time. This means an easy installation.

• 50 Years Service Life

Due to its superior corrosion resistance, FRP Sheet Piling can be installed with the confidence of performance even after 50 years

Specification

FRP Sheet Piling

We can design and produce other sizes according to customer requirements.

Installation

FRP Sheet Piles can either be driven, jetted in or dug and then installed. Driving is the most frequent method for installation of vinyl sheet piling. Frequently a protective steel cap or mandrel is utilised to protect the piling head and ensure more even distribution on the end of the sheet piling of the driving load. Under some conditions an excavator can be used to provide the necesssary download force to press the sheet piling in. A steel mandrel with the same profile as the sheet piling can also be utilised to prepare the soil for the proceeding piling while the current piling is being driven in. High pressure air or water jetting can be used to augment the driving by creating a pressure under the sheet piling foot to loosen and remove the soil directly under it. Digging is the last resort if the soil conditions are rocky and driving or jetting is not feasible.