like large and medium-sized pyrolysis plant, small scale waste plastic pyrolysis plant also uses the principle of pyrolysis to recycle waste plastics, only its daily capacity is 500kg-2000kg, and it takes about 20 hours for one batch. The small scale waste plastic pyrolysis plant is designed in one frame, easy to transport, no installation, no foundation, simple operation and low cost, which is ideal for laboratory or initial exploration stage of the project. In addition, the small scale waste plastic pyrolysis plant can be used not only for waste plastics, but also for recycling waste tires, waste rubber and even waste oil sludge.

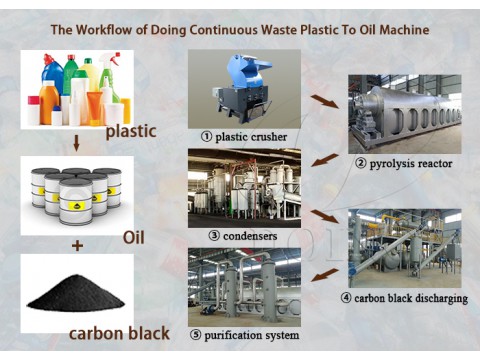

1. Feeding raw materials

Put the dry plastic waste into the pyrolysis reactor, the quantity should be controlled below 2/3 of the pyrolysis reactor to make it rotate more smoothly. Then close the feed door.

2. Heating pyrolysis reactor

The heating of pyrolysis reactor includes two stages: from 100℃ to 250℃ for the primary stage, light oil gas is released at 100℃ and liquid oil is released at 120℃; 280℃ to 350℃ is the highest oil output rate interval. The heavy oil are collected and liquefied in the center of the manifold and descend to the heavy oil tank. The lighter gas rises to the condensing system and then are liquefied and stored in the oil tank. The non-condensable gas after desulfurization and dedusting system will be led to the furnace to heat pyrolysis reactor to save energy costs.

3. Carbon black discharge

At the end of the process, cool the pyrolysis reactor. When the temperature drops to 50-70 degrees, the carbon black will be discharged automatically.

For moreinformation :

Whatsapp:+8613526692320

https://www.wastetireoil.com/

E-mail: market@doinggroup.com

www.continuouspyrolysisplant.com

https://www.doinggroup.com