Circuit board recycling equipment is professionally to process the waste circuit boards to recycle the metals out for profit. The working principle of circuit board recycling equipment is mainly crushing and separation. The metals and non-metals can be separated from waste circuit boards.

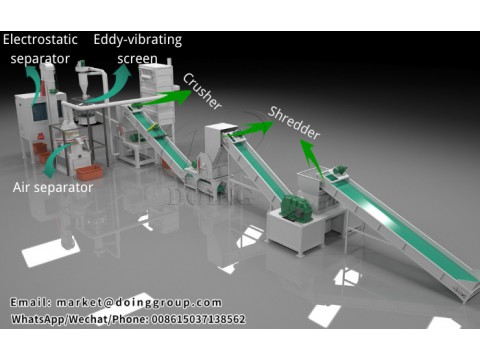

Circuit board recycling equipment process scrap circuit boards through shredding or crushing, eddy-vibrating screen, air separation and electrostatic separation. First, waste circuit boards are shred and crushed into small pieces. And then, eddy vibrating screen sort the big pieces and return to the crusher for second crushing. Air separators use the difference in specific gravity of metals and non-metals to separate them. Electrostatic separator machine performs sorting in a closed high-voltage electric field according to the different conductivity of metals and non-metals. After the process, the separated metals and non-metals are very pure.

Compared to the old ways to process the circuit boards, like directly burning or labour dismantling, the biggest difference for the working principle of circuit board recycling equipment is the machine adopts dry type physical separation method, no use fire or water, thus will not produce any secondary pollution to the environment. After the whole process, the metal recycling rate can be reaching to 99%, almost all the metals contained in the circuit boards can be recycled. Through this kind of working principle of circuit board recycling equipment, it can cause less resources loss and make full use of the waste energy.

After the above introduction of the working principle of circuit board recycling equipment, believe you have got a general understanding of this machine. So if you are interested in knowing more information about this circuit board recycling equipment, just feel free to contact us DOING company.