Plastic Product Design Vannova

Prior to injection molding, the movable mold and the fixed mold are closed under the driving of the injection molding machine to form the cavity and the gating system; and the plasticized plastic melt is injected into the cavity by the gating system for cooling solidification, upon cooling solidification, the movable mold and the fixed mold are opened, and plastic parts are ejected by the demolding mechanism.

I. Classification of injection molds

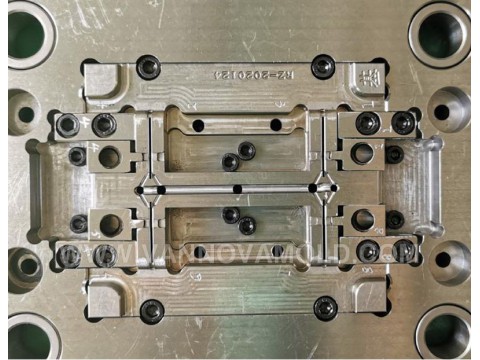

Composition of injection molds

Two major parts:

Movable mold (installed on the movable mold plate of the injection molding machine)

Fixed mold (installed on the fixed mold plate of the injection molding machine)

Prior to injection molding, the movable mold and the fixed mold are closed under the driving of the injection molding machine to form the cavity and the gating system; and the plasticized plastic melt is injected into the cavity by the gating system for cooling solidification, upon cooling solidification, the movable mold and the fixed mold are opened, and plastic parts are ejected by the demolding mechanism.

Injection molding principle

Fig. 3-1 shows the principle of the injection molding of the plunger type injection molding machine

Fig. 3-1 One of injection molding principles 1-Plunger 2-Hopper 3-Spreader 4-Heater 5-Nozzle 6-Fixed mold plate 7-Injection molding part 8-Movable mold plate

designing mouldings company: HEBEI FINE ART CO., LTD.