PCB separator machine is to professionally process the waste printed circuit boards to recycle the metals out for profit. As PCB recycling business becomes more and more popular, the PCB separator machine is well known more too.

The printed circuit boards are everywhere in people’s daily life, such as used mobile phones, scrapped computers, televisions, refrigerators, etc. The electric appliances all have the printed circuit boards. Internal parts of the electric appliances contain lead, nickel, cadmium, mercury and other toxic substances, so when it’s broken, if you dump the waste directly or bury it in the soil, it will cause a lot of pollution to the land and air. Furthermore, you also lost the chance to recycle printed circuit boards for cash. Because the metals contained in the printed circuit boards can be sold and make money completely.

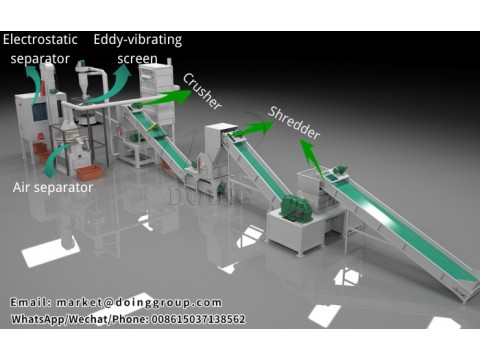

So how does PCB separator machine working? Here is the general processing. With the process of crushing, air separation and electrostatic separation, the metals recycling rate of this PCB separator machine could be reaching to above 99%. So the metals and non-metals could be separated effectively. The non-metals are mainly resin fiber, which is mainly used in wood-plastic industry. Then about the metals, you could sell it directly.

Then as for the features of this PCB separator machine, it’s mainly four points I listed in the following:

a. High separation rate and environmental friendly working process.

b. Machine is working automatically. Usually the whole line only needs one person to operate.

c. There is dust collecting device equipped in the whole process, so it could control the dust flying to ensure the clean of the factory.

d. The voltage can be customized as per your requests.

The above are basically all about the PCB separator machine, if you want to know more, or if you want to start a recycling business , don't hesitate to contact us DOING !