Aluminum plastic separation recycling machine is a device used to separate and recycle aluminum and plastic from waste aluminum plastic composite materials. With a wide range of applicability, It can handle many common materials in life, such as waste aluminum plastic composite panels, aluminum plastic medicine packaging, aluminum plastic decorative board, etc.

In addition, the aluminum plastic separation recycling machine is easy to operate and only requires five steps.

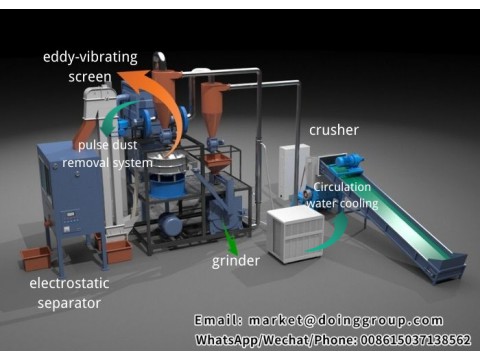

The first step is crushing. Some raw materials are too large to handle. Therefore, a crusher should be used to break them into small pieces.

The second step is grinding. Due to the good adhesion between plastic and aluminum, it is difficult to separate them. So, it is necessary to grind the small pieces with a grinder to make them easy to separate.

The third step is circulation water cooling. During the grinding process, some materials will burn due to the increase in temperature, which will reduce the recycling rate of the aluminum plastic separation recycling machine. The circulation water cooling system can reduce the temperature of the grinder so that the materials will not burned.

The next step is screening. Some pieces that are not completely grind may still be difficult to separate. The eddy-vibrating screen sends these pieces back to the grinding mill to continue grinding. Those completely grind materials will pass through the eddy-vibrating screen to the next step.

The last step is electrostatic separation. According to the different conductivity between aluminum and plastic, the electronic separator can easily separate aluminum and plastic from aluminum plastic composite materials.

After the above process, the aluminum plastic separation recycling machine has completed its work. As for the waste air generated in the processing, pulse dust removal system will collect and clean it. In the end, what will you get is 99% purity of aluminum and plastic.