Product Introduction of high profitable project Investors seeking projects copper wire recycling machine

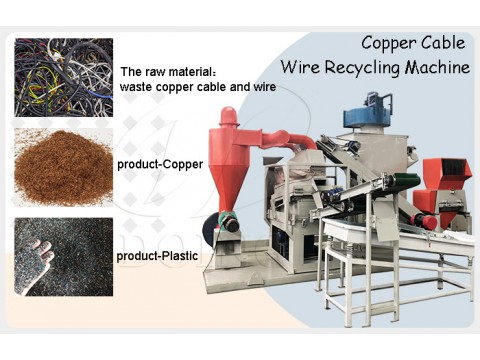

Copper wire recycling machine, also calledscrap copper cable wire recovery machine, which is a kind of environmental protection machine used to recyle waste cable wire, copper wire, aluminium wire, metallic composite wires and sheathed lines.

Through crushing, iron removal, air separation, electrostatic separation process to make completely dry and physical separation of scrap wires to get pure metal and plastic double recycling and achieve high benefit. By equipped with electrostatic separator, the separation rate ofcopper wire recycling machinecould reach to 99%.

Main Features of copper wire recycling machine

Main Features of copper wire recycling machine

1. Integrated type design, copper wire recycling machine

with compact structure, small land occupy size, easy to move to anywhere you want;

2. Copper wire recycling machine adopts PLC control, easy to operate, one operator is enough;

3. The air separator adopts Italian air suspension separation technology, both the vibration frequency and air supply could be accurately adjusted according to the different materials.

4. The crusher use SKD-11 alloy blades, the hardness is H85 degree, which could ensure the good toughness under high wear resistance guarantee with the alternated splayed structure. Also the crusher has the circulation water cooling cover which could avoid the melting of the material under high temperature caused by long time crushing.

5. The whole process is under sealed structure with advanced pulse dust collector, which could ensure no dust fly around during the operation.

6. For very thin wires, like car wires which are less than 3mm, we also have the electrostatic separator which could be equipped with the air separator for further separation, thus to fully separate the thin copper left with plastics.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

♦ Pre-sale Service

(1) According to the customers' special requirements, provide the most suitable project design, process design and the purchase program.

(2) Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

♦ On sale service

(1) Welcome you to our factory for a visiting;

(2) Accompany you to check our machine production, quality and the working conditions.

(3) Customize the equipments strictly according to your special requirements and arrange the timely delivery.

♦ After-sale service

(1) Installation guidance

When the machine arrives at your company, we will dispatch our technicians to your factory to guide the installation and commissioning at site.

(2) Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3) Warranty

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.