I. Definition:

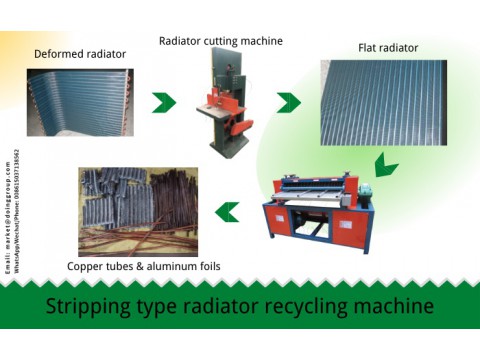

Radiator recycling machine is designed for processing radiators to get copper tubes and aluminum foil blocks. So it is also called stripping type radiator recycling machine.

II. Processing materials:

In general, it can process various radiators, like air conditioner radiators, car copper aluminum water tanks and so on. It can handle single-layer and double-layer copper and aluminum heat sinks with different copper tube spacings of 19mm, 21mm, and 25mm. But these radiators must be flat and intact.

III. Auxiliary equipment:

Radiator cutting machine is the auxiliary equipment of radiator recycling machine. It can cut the multi-layers radiators into one or two layers, and cut the super-wide radiators into the suitable size.

IV. Working process:

The working process of radiator recycling is very easy. After pre-processing the radiators, the size of radiator will be suitable for radiator recycling machine. So just putting the radiators into this machine, you will get copper tubes and aluminum foil blocks.

V. Advantages:

1, High working efficiency - Because it has processing capacity of 300-400 kg/h and 500-600 kg/h, it can process a lot of radiators within a short time.

2, High recovery rate - The recovery rate can reach to 99%.

3, Low cost - It is very easy to operate, which only needs 1 or 2 workers to operate, so you will not spend much money on labor force; besides, it is very small, just needs a small land to install it, therefore you will save a lot of money on land cost.

Radiator recycling machine is one kind of hot-sale production of Henan Doing Environmental Protection Technology Co., Ltd, almost every few days we will sell one. If you are interested in this machine, welcome to contact us.