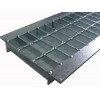

Steel Trench Grates Used as Draining Covers in Waste Water System

Steel grating made of black iron or galvanized provides economical and durable solution for trench covers and drain covers. Qindelin can provide standard trench cover gratings with frame, flange and customize other types according to customer demands and drawings. Our trench cover plate generally consists of the steel grating, the angle iron frame and the embedded part. Surface treatment: Black steel or Hot dip galvanizing.

Flanged Grating Trench Covers, supplied with angle iron frame

Processing and Welding of Trench Grating Covers:

1. High frequency automatic welding machine is used to do welding on the hot dip galvanized gratings and covers (except end plate welding). Melting-corrosion on the based material is not allowed.

2.Material: By CNS SS400 steel or customized

3.Surface Treatment: After grating is formed, the surface is by hot dip galvanization; the thickness of galvanization is 610 g/m2.

4. End Plate Welding: Two sides of gratings are welded on with H*6 mm flat steel.

Welding slag is required to be cleaned.

Features:

Attractive appearance: Simple lines, silver surface and modern conception.

Optimized Draining Design: Water draining area amounts up to 83.3%, which is equal to twice of the cast iron product.

Hot-dip Galvanization for Trench Steel Grates: Strongly rust-proof, need no maintenance and replacement within 30 years.

Anti-theft Design: The draining cover and the frame are connected with chains, which is anti-theft, safe and easy to open.

Saving Investment: Cost less than cast iron product in the case of large span and heavy load, and can save expenses incurred by replacement of stolen or crushed cast iron covers.

Applications: Trench grates are used as draining cover, gully cover and well covers.