Aquafeed made by drifting fish feed making maker is a bait particularly provided for the breeding of marine pets. According to feeding varieties, water feed can be split into fish feed, shrimp feed as well as crab feed; According to feed attributes, it can be divided right into substance feed, concentrated feed and premixed feed.

The raw materials of aquafeed production by drifting fish feed making maker are mostly composed of fish dish, grain resources and oil, as well as fish meal and grain resources frequently make up greater than 50% of the feed expense.

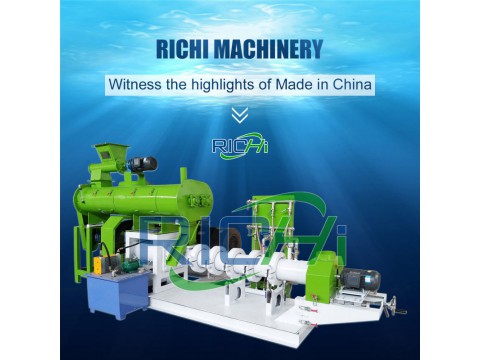

Related post: floating fish feed making machine

The aquaculture floating feed extruder maker makes use of the unequal distance non-standard screw system of the drifting fish feed making equipment to squeeze out, and the gas in the material is released as well as quickly full of the material.

With the rubbing between the stack and also the chamber, the product is fully mixed, pressed, heated, glued and gelatinized by floating fish feed extruder, causing tissue modifications, the initial framework is destroyed, and the mechanical energy is exchanged heat energy through the rubbing of the product in the chamber, so that the product becomes a gel state with streaming residential properties.

When the material is extruded to the outlet, the stress changes from high pressure to regular pressure immediately, and from high temperature to normal temperature level instantly, triggering the dampness to rapidly evaporate from the cells framework, creating it to develop within. Various microporous structures, and then through the reducing tool, reducing and cooling, that is, blowing and also forming.

Related post: fish feed processing line

1. Refine of drifting fish feed making device

Crushing of resources → prep work of raw materials (corn dish, soybean meal dish, starch, fish dish, etc) → mixer → sharing line → twin-screw feed extruder → sharing → drying devices ( electrical oven, gas fuel oven or vapor stove) → oil injection → Dual barrel seasoning system → cooling conveyor line → squashing → screening → warehouse → packaging equipment

This drifting fish feed making machine production line can generate fish tank feed pellets such as catfish, yard carp, crucian carp, tilapia, exotic decorative fish, soft-shelled turtle as well as bullfrog.

2. Functions of floating fish feed making equipment

The floating fish feed making equipment is used in the manufacturing of floating fish feed and also tropical decorative fish feed. The feed has a lengthy suspension time and is not easy to distribute.

By readjusting the drifting fish feed making equipment process and also technical specifications such as basic materials, temperature level, wetness, and so on, the product has the characteristics of novel style, distinct taste, abundant nutrition as well as delicateness. It is applied to the preference of different fish species, and also the suspension time has to do with 20 hrs.

Related post: 15T/H fish feed mill plant

The floating fish feed making equipment is little in dimension, high in output, reduced in power intake, straightforward and convenient in operation, and reduced in failure rate as well as maintenance rate, therefore significantly minimizing maintenance costs

Compared to the twin-screw drifting fish feed making equipment, the triple-screw has 2 even more intermeshing extrusion and treating zones, which is equivalent to 3 collections of twin-screw, with even more shearing times, good homogenization, treating, and also puffing, and also has a vast array of test materials as well as a broad operating array.

Three-screw floating fish feed extruder equipment extruding tooth cavity, strong blending ability, consistent pressure, uniform and also secure pellets, can satisfy the demands of new products for continuous improvement of blending effect.

3. Composition of drifting fish feed making equipment line

The floating fish feed making machine line procedure normally includes raw material obtaining and also cleansing tools, conveying tools, crushing tools, batching tools, mixing tools, drifting fish feed pellet mill, blowing devices, liquid splashing equipment, ventilation as well as dust elimination tools, product packaging devices and also central control system.

( 1) Feed grinder for drifting fish

Suitable for the crushing of grain, straw as well as root; appropriate for the crushing of medium and low hardness products, as well as can squash granular materials such as corn, sorghum, wheat, beans, and cakes. Feeding; it can likewise crush turf, dry weeds, wonderful potato plants, peanut seedlings, corn stalks, dry grain stalks, bean stalks and also other tool as well as reduced hardness straws.

Typically, corn kernels of about 2mm-5mm can fulfill the needs of most people. If the straw is made use of as feed pellets, it can be refined with a 3mm-8mm screen.

Related post: 48T/H tilapia fish food factory

If you want to feed pigs, livestock and also sheep directly after crushing, you can select a 15mm-30mm display; this crusher is an excellent, effective as well as economical equipment for tiny and also medium-sized country pig ranches, professional pig farmers and auxiliary handling families.

The hammer mill for drifting fish feed making machine line has portable as well as reasonable framework, little quantity, reduced noise, reduced power usage, high performance, stable turning, dependable securing, no dirt pollution, good self-cooling feature, practical disassembly and maintenance, straightforward setup as well as hassle-free substitute. harmed parts.

Typically, hammer mills for drifting fish feed making device line are manufactured according to national requirements, and standard parts are also used. If parts are damaged, parts of the very same requirements can be bought as well as replaced, keeping upkeep prices well controlled.

( 2) Feeding screw lift

The screw lift for floating fish feed making machine line is a closed sharing devices, which can convey horizontal, inclined, vertical, long-distance and short-distance sharing; during the sharing procedure, it can efficiently stay clear of environmental pollution caused by overflow and also dirt.

Large size, high precision, great conveying conditions, and can be integrated and placed at will according to the working problems, adaptable and adjustable, can be directly attached as well as repaired with its supporting equipment, no structure is required, and also the space can be totally utilized.

Related post: Richi Machinery

The crushed forage or grain can be sent out straight to The required placement can straight change manual handling, saving time and effort as well as high performance. It is an indispensable tools for continuous processing.

( 3) Feed mixerMixing equipment for drifting fish feed making machine line is likewise among the crucial mechanical equipment in animal husbandry. The typical mixing method is to manually stack the products into piles, interspersed with left and also ideal to cover and stir.

This technique is lengthy and also labor-intensive. For powder ingredients, the blending is not uniform, and also the feeding is compared with the conventional technique, the mixer has the complying with advantages: short mixing time, constant work, reduced energy consumption, diverse features, as well as more uniform mixing.

It can be directly stirred to feed hay to concentrate, or it can be combined with water. When the stirring device for drifting fish feed making maker line is working, the internal screw drives the material near the axis to rotate the axis, the axial direction is pressed from the inside to both sides, as well as the outer screw drives the material close to the cyndrical tube wall.

The product turns around the shaft, as well as the shaft is pushed from both sides to the inside. The blend can be combined consistently in a short time.

Related post: https://www.pellet-richi.com/fish-feed-extruder/floating-fish-feed-machine.html( 4) Fish feed floating pellet making machine

For animal husbandry, it is momentary to wreck the product as well as feed it straight. If the forage is insufficient in wintertime, it will certainly not function, but directly saving the forage will certainly occupy a great deal of area, since the straw forage is cosy as well as takes up a lot of space.

If you do not take preventative measures, it will certainly end up being a breeding place for rodents, waste food, and also spread diseases. The birth of floating fish feed making maker solved this huge problem. The stress in between the two pressures the round pellets out.

Feed pellets normally have different formulas, which are roughly composed of 50% forage, 30% fine-tuned grain, 10% wheat bran, 10% soybean dish as well as a percentage of ingredients. After mixing, add a small amount of water, as well as the general water content of the product accounts for about 15%, which can be processed by a drifting fish feed making machine.

During processing, heat is raised as a result of forced pressurization to minimize germs and bloodsuckers. After the completed product is a little dry, it can be bagged and sealed.

The fish feed pellets refined by the drifting fish feed pellet making device are smooth and round, with excellent shade as well as moderate hardness. The compound feed is developed with a range of resources, which are abundant in nutrients as well as can prevent animals being fussy eaters; the raw materials are controlled automatically, decreasing costs, enhancing nourishment, secure usage and far better digestion.

I really hope the above related web content regarding drifting fish feed making equipment is useful to you. To find out more about floating fish feed pellet production, you are welcome to consult the team of Richi Equipment, we will certainly offer you totally!