Overview

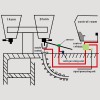

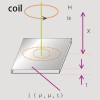

MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition.

The technical parameter

Mold width: 500-2000mm

Mold thickness: 100-500mm

Type: screw conveying type mold flux feeding machine

Heating method: stirring electric heating

Arrangement location: on the pouring platform (with its own wheels to move)

Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube

Molding flux storage tank: ~125 L, with material level detection and alarm

Control mode: local/remote control, automatic /manual mode

Molding flux type: granular flux or powder flux

flux adding method: spiral swing adding flux

Casting speed interlock: yes

Mould size setting: yes

Signal transmission: DP/Industrial Ethernet