Overview

The all-digital non-contact infrared automatic cut-to-length cutting system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-48 billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±1mm, and the system can support 12 strands high-definition CCD image measurement.

The features of the system

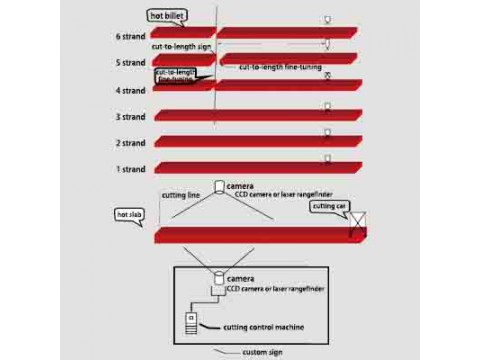

1. The system adopts advanced digital image processing technology (non-contact type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera.

2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-48 billets to length at the same time with an infrared camera.

3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1.

The technical parameters

1. Numbers of caster stands: maximum 12 strands

2. Measurement accuracy: ±1mm

3. Cutting method: flame cutting

4. Fixed length range: 6-12m

5. Matching casting speed: 1.5~4.2m/s

6. Fixed length range: 6-12m

7. Temperature range of cast products: <1000℃

8. Number of signals: pre-cut, cut