As a member of the MEMS industry, Ericco Intertial has been deeply involved in the industry for 15 years. In these years, the MEMS industry has made considerable progress in China, especially during the “13th Five-Year Plan” period. As an important growth point in the sensor field, the development of the MEMS industry is particularly. At present, China has become the fastest growing region in the global MEMS market.

The reason for the rapid development can be attributed to the rapid development of consumer electronics and automotive electronics applications, the rise of 5G, Internet of Things and other industries. The market size of China’s MEMS industry has grown from 36.3 billion yuan in 2016, with an average annual growth rate of 15%. To about 70.8 billion yuan by 2020, far higher than the global growth rate of about 9.6%. The MEMS industry has formed a number of industrial clusters in mainland China. Suzhou, Beijing, Shanghai, Shenzhen, Wuhan, Zhengzhou, Wuxi and other places are vigorously developing the MEMS industry. Many provinces and cities have issued support policies for the MEMS and sensor industries and established Industrial Park.

In the future, the development of my country’s MEMS industry will present the following characteristics:

First, the next ten years will be the golden decade of China’s MEMS industry. Sino-US trade frictions, technology decoupling, and the US’s suppression of certain companies, including the prolonged impact of the new crown pneumonia epidemic, are difficulties that we have to face, and they have also brought a lot of negative effects on our industrial development, especially in the market end. However, external pressure has also brought us opportunities. The first is the opportunity of localization. Companies that did not want to use or dared to use domestic chips before have to use domestic chips. The second is the opportunity of sci-tech innovation board. The era of technological wealth creation has come, and the listing of some MEMS companies has brought a good demonstration. The third is the new infrastructure opportunities, the new demand brought by the 5G and Internet of Things market; the fourth is the opportunity for state support, and the state is increasing policy and capital investment to support the MEMS industry. Therefore, it can be predicted that the next ten years will be the golden decade of China’s MEMS industry. Ericco has been committed to the development of higher performance MEMS gyroscopes. Ericco’s ER-MG2-100 has broken through the low-precision bottleneck of MEMS gyroscopes, and its bias instability has reached 0.02°/h. It makes the development of MEMS gyroscopes to a higher stage.

Second, the innovation capabilities of Chinese MEMS companies urgently need to be improved. The MEMS industry has a bright future, but the independent innovation capabilities of Chinese MEMS companies need to be strengthened. Innovation requires talents. MEMS is different from IC. To make MEMS products, one needs to understand both microelectronics and compound talents who understand power, sound, light, electricity, magnetism, heat and other disciplines. How to train talents is not only for MEMS practitioners, but also for the entire social education system to be strengthened.

Third, foundry manufacturing is an important feature of China’s MEMS industry. The traditional view is that MEMS is a product and a process, not suitable for foundry mode. However, from our experience in operating 6-inch foundries, MEMS processes are gradually being standardized and compatible, and the ratio of MEMS to IC is much smaller. The investment in the IDM model is huge, the operation is difficult, and the company’s comprehensive strength requirements are high. Most MEMS companies are actually more suitable for foundry mode. And we found that through some mechanism innovations, design companies can get rid of the constraints of heavy asset investment while enjoying the advantages of the IDM model with a short development cycle and good quality control.

The current international situation is becoming increasingly complex, and companies generally have the need to avoid risks. At the same time, the domestic MEMS manufacturing level continues to improve, with more rapid response, low communication cost, and obvious advantages in price. Therefore, many companies are actively considering returning manufacturing links to the mainland. This trend is very obvious. This has also led to the acceleration of the construction of MEMS wafer fabs in the mainland, which has further strengthened our country’s MEMS manufacturing capabilities. The local government has played an active role in promoting this.

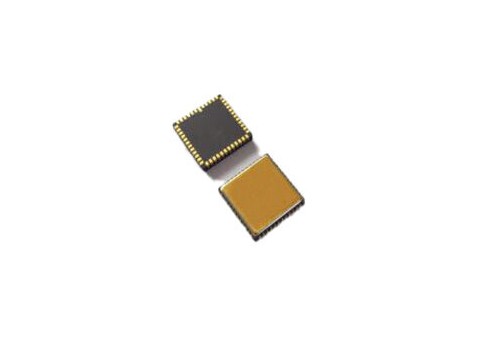

Fourth, advanced packaging is an important part of the MEMS industry. MEMS packaging is an important part of determining the performance of MEMS devices, and multiple functions such as chip protection and external signal interaction must be realized at the same time. The quality of the packaging process largely determines the performance and cost of MEMS products. Compared with IC packaging, MEMS packaging needs to consider more factors, more complex, and different standards, often requiring customization. In recent years, 3D wafer-level packaging technology has made great progress. It is possible to integrate MEMS and ASIC, and further improve efficiency and reduce size are important directions in the field of MEMS advanced packaging. Ericco’s ER-MG2-300/400 is available in a advanced hermetically sealed ceramic LCC surface mount package, so its size only 11 x 11 x 2mm.

Fifth, new materials and sensor integration are new opportunities for the MEMS industry. Silicon-based MEMS has been developed for more than 40 years. How can we greatly improve product performance and reduce costs? MEMS devices based on new materials are a huge opportunity in front of us. For example, PZT, aluminum nitride, vanadium oxide and other new material MEMS devices are making breakthroughs, and the next step is expected to be quickly applied to replace some traditional silicon-based products. At the same time, combining a variety of single-function sensors into a multi-functional sensor module, and then integrating micro-controllers, microprocessors and other chip sensor integration technology, is also a new market opportunity for the MEMS industry.

Ericco’s MEMS IMU INS, FOG DTG gyroscope, MEMS sensor and other equipment have become leaders in the industry in China, and are in a leading position in the industry. Ericco will also seize this opportunity and continue to seek technological innovation.

mems gyroscope wikipedia

3-axis mems gyroscope

mems gyroscope

mems gyroscope uses

types of mems gyroscope

mems gyroscope principle

mems gyroscope datasheet

mems gyroscope price

If you are interested in any of our products, please contact us through any means of the website.