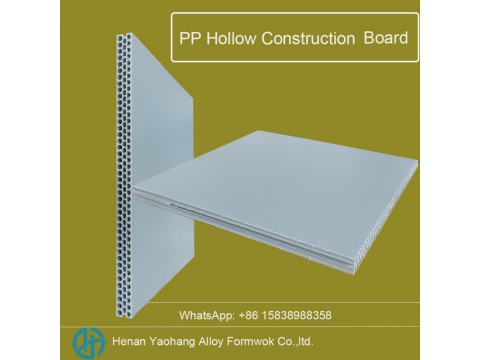

1. Compared with traditional wooden/ steel formwork, plastic formwork( PP hollow construction board) can reduce the cost by 30% because of its features: high strength, good impact resistance, good abrasion resistance, ,reusable at least 50 times and high cost-effective price.

2. It is very suitable for seaside buildings, and water conservancy projects because of its advantages: good waterproof capacity and doesn't deform, crack, and delaminate.

3. It is easy for workers to operate: can be drilled, nailed, sawed, cut, etc. So It is very flexible for workers to use and suitable for all buildings and engineering.

4. It can improve dismantling efficiency by 40% because it is convenient to remove. only tapping, our plastic formwork drops down and there is no need to worry about the damage from dropping down. What's more, shaped concrete structures reach the standard of fair-face and can be directly decorated with veneer, shortening the construction time by 30%.

5. It can be used for special curved surface concrete structures because of its good toughness. We can use a forklift to bend the formwork.

6. With lightweight because of low density and hollow structure in the middle, it is easy for workers to carry and operate and reduce the transportation cost.

7. We don't need brushing oil to save cost and shorten construction time because of its flat and smooth surface and not sticking to the concrete.