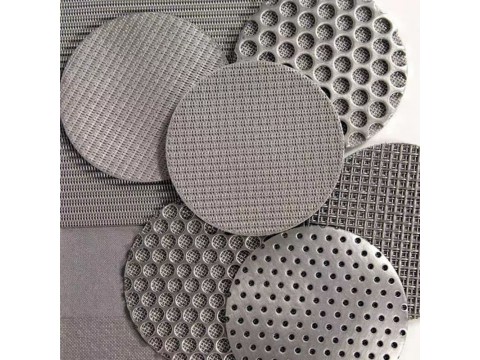

Sintered Wire Mesh is a high-performance filtration material created by bonding one or more layers of woven wire mesh through a precise sintering process. The process begins with roller-flattened wire mesh to ensure uniform contact at wire intersections. These layers are then laminated under mechanical pressure in a high-temperature furnace filled with inert gas, where the wires are diffusion-bonded together. once cooled, the result is a rigid and durable material with enhanced mechanical strength and consistent pore sizes.

This versatile material can be customized into single or multi-layered structures, often incorporating a perforated metal sheet for added reinforcement. Its uniform porosity and robust structure make it ideal for demanding filtration applications, combining excellent durability, thermal resistance, and precise filtration efficiency. Sintered Wire Mesh is widely used in industries such as chemical processing, oil and gas, water treatment, and food and beverage filtration.