Application of hollow glass microspheres in the plastic

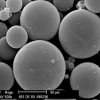

Hollow glass microspheres are used as filler of ultra-high molecular polyethylene. It is not only used as solid lubricant in process, but can modify the comprehensive mechanical properties of the ultra-high molecular polyethylene to improve its strength and abrasion resistance.

Nylon 6 with hollow glass microspheres has a higher tensile strength, impact strength, hardness and other improved mechanical properties and can prevent the material aging caused by the light and heat. With the increase of glass microspheres content, the Martin’s temperature of materials rises. It can used in the production of bearings, cameras, furniture and its accessories;

Hollow glass microspheres are added into rigid PVC to manufacture profiled materials, pipes and plates. These materials have good stability in dimension, then their the rigidity, heat resistance, productivity will be improved;

Filled into ABS,this can improve the size stability of material, reduce shrinkage, improve the compressive strength and flexural modulus, and improve the performance of the surface paint. So it can be widely used in production of TV cabinet, automotive plastic parts;

Filled into epoxy resin,it can reduce the material’s viscosity and improve the mechanical properties. So it can be used in production of composite foam plastic, deep-sea submarine, lifeboat, etc.

Filled into unsaturated polyester. It decreases the shrinkage and water absorption of materials, increase its wear resistance. Meanwhile, less space is produced when laminated and coated. So it can be applied in production of FRP products etc.