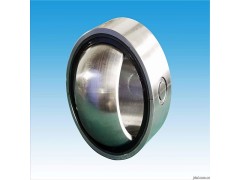

Features:

1) Can bear high load. According to its different types and structures, rod end bearing can bear radial load, axial load as well as two kinds of loads together.

2) Spherical outside surface of inner ring is lined with composite, so it is self-lubricating.

3) Rod end bearings has shock resistance, because of its spherical sliding large contact area, large dip angle and special craft processing method, such as lamenting, zincing, chroming or lining of outside sliding surface, spraying and so on.

4) Rod end bearing has the resistance of corrosion, abrasion. It also can be self-aligning, self-lubricating, so it can work normally even though installed improperly.

Technical performance:

1) Working temperature: -30°C~+80°C

2) Angle of inclination: 3°~15° (angular contact rod end bearing: 2°~3°; thrust rod end bearing: 6°~9°)

Application:

Generally it is suitable for pendulum motion (angular motion) with low speed. Widely used in the industry of engineering hydraulic oil cylinder, metal forming machine, engineering machinery, automation equipment, auto damper, Water Conservancy Machine and so on.

Spherical plain bearing,our company can supply the different types and the different size for each type. Detail technical parameter as follow:

| GEG..ES | Dimensions (mm) | Load ratings | ||||||||

| Type | d | D | B | C | d1 min | Dynamic | Static | a° | Weight (kg) |

|

| GEG 4 E | 4 | 14 | 7 | 4 | 7 | 3.4 | 17 | 20 | 0.0045 | |

| GEG 5 E | 5 | 14 | 9 | 5 | 8 | 5.5 | 27 | 21 | 0.0066 | |

| GEG 6 E | 6 | 16 | 9 | 5 | 9 | 5.5 | 27 | 21 | 0.0081 | |

| GEG 8 E | 8 | 19 | 11 | 6 | 11 | 8.1 | 40 | 21 | 0.0014 | |

| GEG 10 ES | 10 | 22 | 12 | 7 | 13 | 10 | 54 | 18 | 0.021 | |

| GEG 12 ES | 12 | 26 | 15 | 9 | 16 | 17 | 85 | 18 | 0.033 | |

| GEG 15 ES | GEG 15 ES-2RS | 15 | 30 | 16 | 10 | 19 | 21 | 106 | 16 | 0.1049 |

| GEG 17 ES | GEG 17 ES-2RS | 17 | 35 | 20 | 12 | 21 | 30 | 146 | 19 | 0.083 |

| GEG 20 ES | GEG 20 ES-2RS | 20 | 42 | 25 | 16 | 24 | 48 | 240 | 17 | 0.153 |

| GEG 25 ES | GEG 25 ES-2RS | 25 | 47 | 28 | 18 | 29 | 62 | 310 | 17 | 0.203 |

| GEG 30 ES | GEG 30 ES-2RS | 30 | 55 | 32 | 20 | 34 | 80 | 400 | 17 | 0.304 |

| GEG 35 ES | GEG 35 ES-2RS | 35 | 62 | 35 | 22 | 39 | 100 | 500 | 16 | 0.408 |

| GEG 40 ES | GEG 40 ES-2RS | 40 | 68 | 40 | 25 | 44 | 127 | 640 | 17 | 0.542 |

| GEG 45 ES | GEG 45 ES-2RS | 45 | 75 | 43 | 28 | 50 | 156 | 780 | 15 | 0.713 |

| GEG 50 ES | GEG 50 ES-2RS | 50 | 90 | 56 | 36 | 57 | 245 | 1220 | 17 | 1.44 |

| GEG 60 ES | GEG 60 ES-2RS | 60 | 105 | 63 | 40 | 67 | 315 | 1560 | 17 | 1.6 |

| GEG 70 ES | GEG 70 ES-2RS | 70 | 120 | 70 | 45 | 77 | 400 | 2000 | 16 | 3.01 |

| GEG 80 ES | GEG 80 ES-2RS | 80 | 130 | 75 | 50 | 87 | 490 | 2450 | 14 | 6.05 |

| GEG 90 ES | GEG 90 ES-2RS | 90 | 150 | 85 | 55 | 98 | 610 | 3050 | 15 | 5.22 |

| GEG 100 ES | GEG 100 ES-2RS | 100 | 160 | 85 | 55 | 110 | 655 | 3250 | 14 | 6.05 |

| GEG 110 ES | GEG 110 ES-2RS | 110 | 180 | 100 | 70 | 122 | 950 | 4750 | 12 | 9.68 |

| GEG 120 ES | GEG 120 ES-2RS | 120 | 210 | 115 | 70 | 132 | 1080 | 5400 | 16 | 14.72 |

| GEG 140 ES | GEG 140 ES-2RS | 140 | 230 | 130 | 80 | 151 | 1370 | 6800 | 16 | 19.01 |

| GEG 160 ES | GEG 160 ES-2RS | 160 | 260 | 135 | 80 | 176 | 1530 | 7650 | 16 | 20.02 |

| GEG 180 ES | GEG 180 ES-2RS | 180 | 290 | 155 | 100 | 196 | 2120 | 10600 | 14 | 32.21 |

| GEG 200 ES | GEG 200 ES-2RS | 200 | 320 | 165 | 100 | 220 | 2320 | 11600 | 15 | 45.28 |

| GEG 220 ES | GEG 220 ES-2RS | 220 | 340 | 175 | 100 | 243 | 2550 | 12700 | 16 | 51.12 |

| GEG 240 ES | GEG 240 ES-2RS | 240 | 370 | 190 | 100 | 263 | 3050 | 15300 | 15 | 65.12 |

| GEG 260 ES | GEG 260 ES-2RS | 260 | 400 | 205 | 120 | 285 | 3550 | 18000 | 15 | 82.44 |