High refractive glass beads (reflective powder) is the mainreflection characteristics. The so-called regression reflection is an optical phenomenon, when light strikes the lens like objects,refracted from aggregation, focus lens refractive regressionafter reflection and light source direction. Products with high refractive index glass beads as the aluminum to reflector, withretro reflective properties strong, can be directly reflected back to the light source light 85%. Reflective brightness caused byreflection, can make the driver and with light night workers at night or in the case of poor vision clearly see the pedestrian and the obstacle, ensure the safety of both sides.

Yu Mingjie paints reflective powder has good fluidity, pure color,high transparency, high temperature resistance, high level of antioxidant, reflective effect. Be cheap and at the same time very good.

Reflective powder for high refractive glass beads, refractive index of 1.93 ≤ ND ≤ 2.2, opaque rate: ≤ 1%, round rate: 95%.Color can be divided into white and grey two. Reflectivebrightness with reflective powder adding amount of change.

Two, the scope of application of the reflective powder:

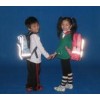

Yu Mingjie paints reflective powder is the production of reflective fabric, reflective film, reflective coating core raw material,reflective signs, promotional materials, clothing materials,standard runway, shoes and hats, bags, life-saving suppliesnew optical functional composite materials. It has the characteristics of return reflection and caused strong retro reflective effect, without external power supply, can be widely used in roads, ports, mines, fire and other areas. As safety signs, greatly improves the reliability and security of users.Widely used in screen printing, reflective paint, reflective ink,traffic signs, reflective material, etc..

Three, reflective powder use techniques:

Method of use: can be directly added to the ink, made of reflective ink, screen printing or brush to fabric or other items,simple operation, easy to master. Add the amount according tothe number of add reflective brightness.

Method two: first bottom coating printing paste, coated reflectivepaste - drying and curing

Reflective slurry preparation: according to the amount, thereflective powder weighing the first solvent (cyclohexanone) to tune into a paste, then, into the transparent printing paste,evenly using. In printing, the printing of the thickness of the adhesive layer to thin, with 30 microns ~50 microns, to ensure that the reflective powder can semi exposed on the surface, thereflective effect. Can according to use, the coarse and fineparticle size, have all kinds of reflective effect. (particle sizerange, reflecting the better)