1 free samples

2 prompt deliver

We could supply all kinds of PE resin from the well-known manufacturer. And have been in ths line of business for

If any question, kindly send me a inquiry! The quotation will be send to you within ONE DAY!

1. Basic Information:

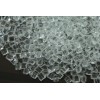

Linear low density polyethylene/ LLDPE resin Granules/pellet/LLDPE Virgin or recycled Grade, LLDPE Film Grade

2. Grade:

Blown film, Cast film, Healthcare, masterbatch compounding, Pipe extrusion, Rotational moulding, Sheet extrusion, Wire & Cable extrusion

3. Application:

Wire & cable, Geomembranes, Containers & pails, Irrigation, Houseware & appliances Thin wall packaging, Stretch wrap, food wrap, Diaper, Lamination & industrial film, Agricultural & indutrial film, Cast film Stretch film, General purpose film Heavy duty film

4. Data Sheet:

1 LLDPE resin for Packing film:

|

PROPERTY |

UNIT |

SPECIFICATION |

TEST |

|

Melt Flow Index |

g/10min |

≤2.0 |

ASTM D1238 |

|

Density |

g/cm3 |

≤0.945 |

ASTM D1505 |

|

Tensile strength |

Mpa |

≥14.0 |

ASTM D638 |

|

Elongation at break |

% |

≥600 |

ASTM D638 |

|

Brittle temperature at low temperature |

°C |

≤-76 |

ASTM D746 |

|

ESCR ,FO |

H |

≥500 |

ASTM D1693 |

|

Oxidation induction period at 200°C |

Min |

≥30 |

-- |

|

Content of Carbon black |

% |

2.60±0.25 |

-- |

|

Carbon Black dispersion |

-- |

≤3 |

GB2951 |

|

Tensile strength after thermal aging |

Mpa |

≥13 |

GB/T2951.12-2008 |

|

Elongation after thermal aging |

% |

≥500 |

|

|

Dielectric strength |

Mv/m |

≥25 |

ASTM D149 |

|

Volume resistivity |

Ω.m |

≥1*1014 |

ASTM D257 |

|

Dielectric Constant |

-- |

≤2.80 |

ASTM D1505 |

2. Specifications:

|

PROPERTY |

UNIT |

SPECIFICATION |

|

Melt Flow Index |

g/10min |

≤1.0 |

|

Density |

g/cm3 |

≤0.945 |

|

Tensile strength |

Mpa |

≥14.0 |

|

Elongation at break |

% |

≥600 |

|

Brittle temperature at low temperature |

°C |

≤-76 |

|

ESCR ,FO |

H |

≥500 |

|

Carbon Black dispersion |

-- |

-- |

|

Tensile strength after thermal aging |

Mpa |

≥13 |

|

Elongation after thermal aging |

% |

≥500 |

|

Dielectric strength |

Mv/m |

≥25 |

|

Volume resistivity |

Ω.m |

≥1*1014 |

|

change rate of tensile strength after weather aging environment of 0--1008h |

% |

±25 |

|

change rate of elongation after weather aging environment of 0--1008h |

% |

±25 |

|

change rate of tensile strength after weather aging environment of 504--1008h |

% |

±15 |

|

change rate of elongation after weather aging environment of 504--1008h |

% |

±15 |

5 Payment: 30% TT in advance, the balance against copy of B/L, or LC at sight

6 Packing: 25kg/pp woven bag, or jumpo bag

7 Loaded: 18mt for 20 foot container, and 26mt for 40 foot container

8 Delivery time: 15days to 25 days