|

Flame Retardant Grade

|

Specification

|

Bead Size(diameter)

|

Expandable Rate (one time)

|

Foam Density

|

|

mm

|

times

|

g/l

|

||

|

QJ-202

|

1.60-2.50

|

70-85

|

3-5

|

|

|

QJ-301

|

1.20-1.65

|

60-70

|

5-8

|

|

|

QJ-302

|

1.00-1.25

|

50-65

|

7-11

|

|

|

QJ-303

|

0.75-1.00

|

50-60

|

9-15

|

|

|

QJ-401

|

0.65-0.80

|

45-55

|

14-18

|

|

|

QJ-501

|

0.45-0.85

|

35-50

|

18-above

|

|

|

QJ-601

|

0.40-0.50

|

30-40

|

18-above

|

|

|

QJ-701

|

0.25-0.40

|

30-40

|

18-above

|

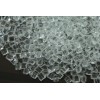

1. Characteristics:

Good flame-retardant, good frothing good preserving, good binding and low heat-conducting rate. Oxygen index over 30 (testing after 7-14 days flowing)

2. Application:

This Flame retardant grade EPS can be used as building-materials, materials for heat preservation, thermal insulation and for packing precision instruments

3. Storage:

The EPS series products of our company need to be put on the place where it is cool and

ventilated, keep the storage temperature below 20°C in order to minimize the lost of

frothing agents from escaping. The lower the temperature is, the better the quality is. The

products should avoid rain, fog, snow and lighting up from the sun, static electricity and

flame. Once the package material of the products is open, it should be used up as quickly

as possible. Otherwise, the remaining EPS might lose its function due to escaping of

foaming agents. If the EPS is stored too long, the expandable times might decrease.

4. Packaging: 25kg/paper bag, 17Tons/20ft Container