Overview:

Dye materials in general have greater pre-drying adhesive to a large extent reduce the drying efficiency of drying equipment, a direct result of investment in equipment and operating costs increased, the average drying equipment is difficult to meet the requirements. I have, through continuous innovation, design and production of the dye-specific production line.

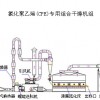

The line from the material pre-forming machine, automatic feeding device and a dedicated shop with drying units and accessories. Drying, the material first by pre-forming mechanism of granulated, and then by the automatic feeding device even ground floor shop to bring in the net, with mesh with the forward movement of materials by the hot air blow drying to achieve the purpose of leaching.

Features:

1 , High yield, good quality

Pre-forming machine materials can be processed into cylindrical or strip, granular and other geometric shapes, an increase of heated area, improve the drying efficiency, while avoiding the sticky because of the adverse factors of materials to achieve high-volume continuous production.

2 , Automatic control, ensure that the drying and stability

Temperature control, and according to materials in different stages of the best temperature for drying various stages of drying temperature set. Stepless transmission speed, the ability to easily control the drying time of materials to ensure product quality.

3 Unique structure

The device's unique structure, radiator placed on the side of the divided air board adopts the form of plates, sub-style uniform.

4, Easy cleaning

According to the characteristics of dye drying easy to pollution, minimize the dead, cleaning very convenient.

Application:

Apply pigments, dyes paste, paste drying, can also be used polymers, iron oxide, iron salts, fluorite, fertilizer, feed and other kinds of granular, flake drying process.