Overview:

With the development of Chinese medicine and flavoring agent market, further active at home and abroad on the Chinese herb extracts, flavors, spices, condiments and other materials increased demand. Meanwhile, with the state of medicine, food production enterprises access system, and foreign imports continue to test the materials, the traditional production equipment can not meet the actual requirements.

For the Chinese medicine extract, flavor, spices, condiments and other material properties, our company on the spray drying process was dedicated research and design, through innovation and user test the actual use of repeated appraisals, design and production company the Chinese medicine extract, flavoring special dryer, all with high quality stainless steel machine is able to satisfy GMP And export standard requirements.

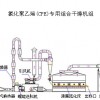

Machine and heated by the air purification system for materials and fogging systems, dry cooling system host and mezzanine, gas - Solid separation systems, refrigeration dehumidification system, pneumatic conveying systems and control systems aggregate the seven major components.

Features:

1 , Strictly according to GMP To design

With the early, middle and inferior high air purifier filters, air treatment can be achieved 10 To 30 10 000; and internal air and material contact with the ingredients of high quality stainless, and polished the surface to make fine; all pipes are to avoid dead ends, star discharger, the main pipe can be easily washable. So as to achieve corrosion resistance, do not fall off foreign bodies, no positive material, easy to clean and does not cross-contamination requirements, full compliance with GMP Standard.

2 , Drying stability, a high degree of automation to ensure the finished product color, flavor, flavor stability.

This machine adopts frequency conversion stepless speed regulation of electric nebulizer and the feeding pump, can be adjusted in a wide range, changing the aerosol effect, so that granularity can be effectively controlled; hot air distributor with Wind and devices, can regulate the hot air in the drying tower running track, helping improve the drying efficiency and product quality; automatic control system can be used PLC Process control system circuit, and using advanced fuzzy control methods may be appropriate under the