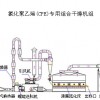

Overview:

Functional ceramics drying, high drying temperature requirements, product requirements grains, eventually the water is low, the cleaning of dryer has a high demand, otherwise it will affect the whiteness. For material properties, our company designed to produce functional ceramic dryer, pressure spray drying using counter-current principle with full use of heat, stable production, product quality and superior features, users now have normal use of Changzhou, in Production 1000 Tons, used to run well.

Features:

1 , The use of advanced countercurrent drying, drying efficiency

Drying process, the droplet and the hot air running in the opposite direction, to improve the material and the relative velocity between the air so that moisture is quickly evaporated, to improve the drying efficiency.

2 , Air clean, bright and clean inside, to ensure product color

Equipment interior all in stainless steel production, and for fine polishing, to prevent material adhesion; with special high-temperature inlet air filter, so that clean air into the drying tower, to prevent contamination of materials to ensure product quality.

3 , Drying stability, a high degree of automation

This machine adopts high-quality high-pressure wear-resistant high-pressure nozzles and variable speed feed pump output can be adjusted in a wide range of feed pressure and the conveying speed, change the atomization effect, so that products can be effective control of particle size; use advanced hot air distributor, so that hot air vertically downward mobility, helping improve the drying efficiency and product quality; automatic control system can be used PLC Process control system circuit, and using advanced fuzzy control methods may be appropriate under the