Overview:

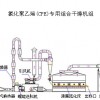

Dextrin as the use of a wide range of raw materials, increasingly used in pharmaceutical, food processing production. Currently, users of the dextrin product requirements have been gradually increasing. However, dry areas is the key to dextrin production, directly affect the product's color, size, etc.. My company for the product characteristics, design and production of Dextrin and vegetable protein-specific Pressure Spray, aircraft from the air purification and heating system for materials and fogging systems, drying the host system, gas - Solid separation system and control system components. Drying process, the feed liquid under the action of dedicated high-speed high-pressure pump through the spray nozzle, liquid is atomized into many small droplets, and full contact with the hot air rapid drying.

Features:

1 , Stable, controllable

This machine adopts high-quality high-pressure nozzle and a dedicated high-pressure feed pump output can be adjusted in a wide range of feed pressure and feed rate input, changing the atomization effect, Wu Hua control of very good, can be dry and requirements of products with different grain size . Meanwhile, the device uses low-temperature hot air drying technology and a new distributor, so that hot air flow uniformity in the drying tower, wind speed and stability, to ensure product quality and stability of the dry.

2 , By GMP To design, air clean, bright and clean inside, to ensure product color

Equipment interior all in stainless steel production, and for fine polishing, to prevent material adhesion; into the outlet with the beginning, middle and high air filters Asia to enter the drying tower of air cleanliness to 10 10 000 or more, to prevent contamination of materials to ensure product quality, consistent with GMP Related requirements.

3 , A high degree of automation

Automatic control system can be used PLC Process control system circuit, and using advanced fuzzy control methods, the data set according to the corresponding program to automatically track control inlet temperature, air temperature, conveying speed, pressure and other relevant parameters, the temperature can be controlled