Overview:

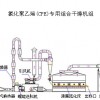

With the food and pharmaceutical industry equipment requirements continue to increase, ordinary fluidized bed has not meet the relevant requirements. The same time, heavy equipment, covering a large, high investment, the aging of rubber mat is easy, serious waste of energy and many other defects, limiting the ordinary fluidized bed application in practice. I am in absorbed foreign advanced technology based on the fluidized bed, with technical innovations, after many changes and improvements to design a new type of linear vibrating fluidized bed drying (cooling) machines, technology has been synchronized with the international and meet GMP requirements. My company has exported to Malaysia agent successfully used in the production of coffee creamer in the domestic health care products have been successfully applied in granules, chicken, fumaric acid, etc., were widely acclaimed by users.

Features:

1 , Equipment vibration isolation using springs instead of rubber mat, greatly increased the service life, while greatly reducing operating noise pollution machine, equipment run smoother, more uniform material flow technology.

2 , Temperature controlled, easy to operate

Advanced temperature control system can precisely control the drying temperature and stable temperature control In "/span>

Total: 0 [Show All] Related Reviews