Overview:

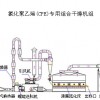

PAM is a polymer with a higher viscosity, on the drying temperature is also very sensitive to drying requirements are special. Our features for polyacrylamide, development and design of special fluidized bed dryer, using a special hot air distributor, the use of linear vibration theory continuous drying drying to achieve a continuous mass production of the material.

Features:

1 , To avoid the adhesion of materials, high yield, good quality

First of all, the extruded material machined into cylindrical or strip, granular and other geometric shapes, and then drying, an increase of heated area, improve the drying efficiency, while avoiding the sticky because of the adverse factors of materials to achieve high-volume continuous of production.

2 , With special sub-style plate, durable, sub-style uniform, well dispersed, dry contact area, during the drying process to ensure that materials are not adhesion, is very beneficial to dry polyacrylamide.

3 Temperature precisely controlled to ensure product quality

Machine with sub-temperature control system, precise temperature control the drying process, to ensure finished products meet the color requirements.

4 , Equipment vibration isolation using springs instead of rubber mat, greatly increased the service life, while greatly reducing operating noise pollution machine, equipment run smoother, more uniform material flow technology.

5 Removal efficiency

By Cyclone combination with pulse bag filter dust removal system, dust removal efficiency of up to 99.8% .

6 Operation and easy cleaning

Machine with circular structure, internal design with no dead ends, and has several clean the door, so very convenient to operate and clean.

7 According to different production requirements, can be used combination drying system, drying effect is ideal.